Difference between revisions of "Electronics and Rapid Prototyping"

Mike Hutton (talk | contribs) |

|||

| Line 70: | Line 70: | ||

|- | |- | ||

| [[File:arksen992D.jpg|200px]] || [[media:RD-500 II rework station manual.pdf|Soldering Station with Heat Gun]] ||Arksen || 992D|| 110 || Working || [[User:James A Seymour|James Seymour]] | | [[File:arksen992D.jpg|200px]] || [[media:RD-500 II rework station manual.pdf|Soldering Station with Heat Gun]] ||Arksen || 992D|| 110 || Working || [[User:James A Seymour|James Seymour]] | ||

| + | |- | ||

| + | | [[File:Micro_Mill_Drill.gif|200px]] || [[media:Micro Mill Drill manual.pdf|Micro Mill / Drill]] ||Central Machinery || 47158|| 110 || Working || [[User:James A Seymour|James Seymour]] | ||

|- | |- | ||

| [[File:Fireball_v90.jpg|200px]] || [[V90|3-axis CNC Machine]] || Probotix || Fireball V90 || 110 || Working || ?? | | [[File:Fireball_v90.jpg|200px]] || [[V90|3-axis CNC Machine]] || Probotix || Fireball V90 || 110 || Working || ?? | ||

Revision as of 22:43, 26 December 2015

Details: missing details and access policies

Contents

General Information

MakeICT's Electronics and Rapid Prototyping lab is an enclosed 200 sq ft area dedicated to creating and debugging electronics, as well as some rapid prototyping capabilities.

James Seymour is the Benevolent Dictator over the electronics and rapid prototyping lab.

Classes

Machine Access Policy

Clean up! Users are responsible for clean up after themselves; failure to which may result in loss of E&RP Privileges, and may require corrective training to regain those privileges. Corrective training is up to the BD, and he is very creative.

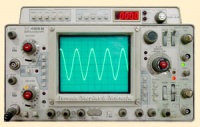

Scopes

MakeICT has a few Oscilloscopes. Most notably is the Tektronix 465B We are fortunate to have some nice ones. Using the Oscilloscope takes some finesse and it's best you have some help with it if you're fairly new to one, so we require certification. The Oscilloscope shows Voltage over time, similar to a graph. There is lots of settings, dials, and switches. if you want to learn to use it just ask to be taught from a reasonably knowledgeable member.

- List of known Scope users is listed below

- Tom McGuire

- James Seymour

Spectrum Analyzer

We have a very nice Spectrum Analyzer (Tektronix 492 AP). The Spectrum Analyzer shows receive power over frequency. So if you set it properly you would see Peaks where each Wifi network is transmitting. It is easy (and expensive) to damage the input of a Spectrum Analyzer. We ask you are certified and use proper caution. We have several attenuators available for impedance matching, so use them.

- List of known analyzer users is listed below

- James Seymour

Circuit Design and Fabrication

Use of the Curcuit Board Mill and or SMD Circuit Work Station requires attendance in the Circuit Design and fabrication workshop or certification from an approved peer-certifier. We do not mind if your circuit doesn't work, we do mind if our equipment doesn't.

- Any member who has been certified to use the circuit fabrication equipment may peer-certify other members

- Certification instruction must at least include

- Fundamental knowledge of circuit board milling principles

- Fundamental knowledge of soldering and solder reflow

- Proper use and control of the LinuxCNC software

- Basic circuit design

- Certification must be documented (link to instructions or form) prior to use

- List of circuit fabrication users below

V90 CNC router

Use of the V90 CNC router requires attendance in CNC Router certification workshop

- Certification must be documented (link to instructions or form) prior to use

- List of CNC Router Certified users is listed below

'The Beast' RD-500S II rework Machine

The Beast isn't up and running yet. It requres some TLC and is considered a work in progress. Once operational, it is designed to make short work of SMD replacement, by combining a CNC rework station with an on board reflow process. Operation will be mostly peer Certification.

Electronics and Rapid Prototyping Safety

- Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help.

- Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify the BD OR Tom McGuire.

- NEVER ASSUME A TOOL IS PROPERLY ADJUSTED. Always check the tool prior to use.

- NEVER MODIFY OR HACK MACHINERY WITHOUT CONSENT FROM THE AREA BD.

Equipment List

| Picture | What | Manufacturer | Model | Power | Status | Expert |

|---|---|---|---|---|---|---|

|

RD-500S II Area Array Rework System | Den-on Instruments | RD-500S II | 110 | Not yet | James Seymour |

|

Logic Analyzer | Tektronix | 1240 | 110 | Working | James Seymour |

|

Tektronix 492 AP | Tektronix | 492P | 110 | Working | James Seymour |

|

Oscilloscope | Tektronix | 465B | 110 | Working | James Seymour |

|

Lead Free Reflow Oven | Qinsi Technology | QS-5100 | 110 | Working | James Seymour |

|

Soldering Station with Heat Gun | Arksen | 992D | 110 | Working | James Seymour |

|

Micro Mill / Drill | Central Machinery | 47158 | 110 | Working | James Seymour |

|

3-axis CNC Machine | Probotix | Fireball V90 | 110 | Working | ?? |