Difference between revisions of "Laser Cutter"

| (38 intermediate revisions by 4 users not shown) | |||

| Line 7: | Line 7: | ||

|laserType = Sealed CO2 laser tube | |laserType = Sealed CO2 laser tube | ||

|bedHeight = ~10 inches | |bedHeight = ~10 inches | ||

| − | |cutSpeed = | + | |cutSpeed = 300 mm/s |

| − | |engraveSpeed = | + | |engraveSpeed = 600 mm/s |

|engraveResolution = 1000 DPI | |engraveResolution = 1000 DPI | ||

|manual = RL-80-1290_User_Manual.pdf | |manual = RL-80-1290_User_Manual.pdf | ||

| Line 18: | Line 18: | ||

An authorization workshop, hosted by an approved instructor, is required of all members before using the laser cutter. Workshops are posted on the [http://makeict.org/calendar calendar]. Peer authorization is not an approved path for use of the laser cutter. | An authorization workshop, hosted by an approved instructor, is required of all members before using the laser cutter. Workshops are posted on the [http://makeict.org/calendar calendar]. Peer authorization is not an approved path for use of the laser cutter. | ||

| − | Interfacing with the laser cutter is performed with [[ | + | Interfacing with the laser cutter is performed with [[Lightburn]]. |

The laser cutter does require regular cleaning and alignment. This is to be performed by trained volunteers only. | The laser cutter does require regular cleaning and alignment. This is to be performed by trained volunteers only. | ||

| − | == Usage == | + | '''NOTE: The focal length of the lens in Luigi is 63.5mm and not 50.8mm like Mario. The longer focal length is better for cutting, but not as good for engraving.''' |

| − | === Safety === | + | |

| − | ==== Fire Safety ==== | + | ==Usage== |

| + | ===Safety=== | ||

| + | ====Fire Safety==== | ||

Laser cutters pose a fire hazard. A high intensity beam of laser light can produce extremely high temperatures as it comes into contact with the materials it is engraving, marking, or cutting. When using the laser cutter, remember: | Laser cutters pose a fire hazard. A high intensity beam of laser light can produce extremely high temperatures as it comes into contact with the materials it is engraving, marking, or cutting. When using the laser cutter, remember: | ||

| − | # You may only use the laser cutter if you have been officially authorized according to the machine access policy | + | |

| − | # '''Never''' leave the laser cutter unattended while it was powered on (even if it is not firing) | + | #You may only use the laser cutter if you have been officially authorized according to the machine access policy |

| − | # '''Never''' cut materials that you don't know are safe | + | #'''Never''' leave the laser cutter unattended while it was powered on (even if it is not firing) |

| − | # '''Never''' override laser cutter safeties and switches | + | #'''Never''' cut materials that you don't know are safe |

| − | # Know what to do if a fire happens | + | #'''Never''' override laser cutter safeties and switches |

| − | ## Move the head out of the way, if it's small. | + | #Know what to do if a fire happens |

| − | ## Hint: Hit the big, <span style="color:red">red</span>, emergency stop button. This will shutdown the laser and the air supply | + | ##Move the head out of the way, if it's small. |

| − | ## A Carbon Dioxide (CO<sub>2</sub>) fire extinguisher is located next to the laser cutter | + | ##Hint: Hit the big, <span style="color:red">red</span>, emergency stop button. This will shutdown the laser and the air supply |

| − | ## Verify it is out and then: | + | ##A Carbon Dioxide (CO<sub>2</sub>) fire extinguisher is located next to the laser cutter |

| − | ### Place a note that a fire occurred and the machine is out of service. | + | ##Verify it is out and then: |

| − | ### Post on the [http://makeict.org/forum forum] about it, or send an email to [mailto:fablab@makeict.org fablab@makeict.org] | + | ###Place a note that a fire occurred and the machine is out of service. |

| − | ### Someone from the laser group will check the machine, clean as necessary, and put it back into service. | + | ###Post on the [http://makeict.org/forum forum] about it, or send an email to [mailto:fablab@makeict.org fablab@makeict.org] |

| − | ==== Eye Safety ==== | + | ###Someone from the laser group will check the machine, clean as necessary, and put it back into service. |

| + | |||

| + | ====Eye Safety==== | ||

The laser is encased and will not fire unless the doors are shut. Do not bypass any safety lockouts or open panels without consulting the fablab lead first. Lasers can cause serious eye damage, even indirectly through scattered energy. | The laser is encased and will not fire unless the doors are shut. Do not bypass any safety lockouts or open panels without consulting the fablab lead first. Lasers can cause serious eye damage, even indirectly through scattered energy. | ||

| − | ==== Air Safety ==== | + | ====Air Safety==== |

Many materials give off toxic fumes when cut. Do not cut unapproved, unknown or banned materials on the laser cutter. See the list of approved/banned materials on this wiki | Many materials give off toxic fumes when cut. Do not cut unapproved, unknown or banned materials on the laser cutter. See the list of approved/banned materials on this wiki | ||

| − | === | + | ===Workflow=== |

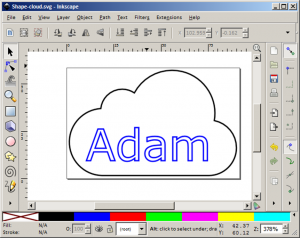

| − | # | + | [[File:Laser cutter design - inkscape.png|thumb|Design step 1: Create your design in your favorite graphics program]] |

| − | # | + | #[[Designing for the laser cutter |Create your design]] on another computer |

| − | # Make sure the air compressor and the | + | #LightBurn ([[Lightburn|detailed steps]]) |

| − | # ''' | + | ##Import your file into Lightburn |

| − | # | + | ##Set up layers |

| − | # | + | ###Fill (start with 100mm/s speed, 20% power) |

| + | ###Line (start with 20mm/s speed, 50% power) | ||

| + | ##Re-order layers so the outermost path is at the end | ||

| + | ##Verify design size | ||

| + | ##Preview laser paths (TV button) | ||

| + | ##Set job origin based on desired laser head starting point (green dot) | ||

| + | #Turn on the machine | ||

| + | ##Turn on the laser cutter using your badge and the green button | ||

| + | ##Make sure the air compressor, blower fans, and chiller are on | ||

| + | ##Wait for homing sequence to complete | ||

| + | ##Lower the bed (z button, then arrows) until material will easily fit under the head | ||

| + | ##Load material onto laser cutter bed | ||

| + | ##Jog head to center of media using control panel (z/esc to switch modes) | ||

| + | ##Raise table until material is 7-8mm below head | ||

| + | ##Jog head to desired starting point | ||

| + | #Return to Lightburn | ||

| + | ##Press "Frame" to outline your job and check that it fits | ||

| + | ##Gently lower lid until closed | ||

| + | ##In Lightburn, press "start" (play button) | ||

| + | #Do not leave laser cutter unattended | ||

| + | #After cut is finished allow ~30 seconds before opening to vent smoke/fumes | ||

| + | |||

| + | [[File:Laser cutter design - sample shape.jpg|thumb|Sample of hardboard - Letter shapes are engraved, outline is cut]] | ||

| + | |||

| + | ===When Finished=== | ||

| + | |||

| + | #Home the head | ||

| + | #Remove media and clear debris | ||

| + | #Power off | ||

| + | |||

| + | ===Rotary Axis=== | ||

| + | If you are using the rotary axis, refer to [[Laser_Cutter_Rotary_Axis | this page]] | ||

| + | |||

| + | ===Troubleshooting Guide=== | ||

| + | |||

| + | *'''Bed only travels downwards''' | ||

| + | |||

| + | #Wiggle the probe and make sure its not jammed | ||

| + | #Check to see if the upper z-limit switch is stuck | ||

| + | #If none of these work, notify the fab lab team [mailto:fablab@makeict.org fablab@makeict.org] | ||

| − | + | *'''Head does not home properly, move very slowly in Y axis''' | |

| − | |||

| − | # | + | #The machine is probably in rotary mode |

| − | # | + | #Turn the machine on, hit 'esc' on the control panel to cancel homing, and disable the 'Enable rotary' setting in the control box with the 'Start' and 'Stop' buttons |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *'''Machine won't turn on''' | |

| − | # | + | #If the lights don't turn change when you scan your badge, unplug machine power for 5 seconds and re-plug |

| − | # | + | #If the light turns red when you scan your badge, you are not authorized for the lasers |

| − | # | + | #If the light turns green but the machine does not turn on, make sure the power switch is pressed and the emergency stop is not pressed |

| − | + | #The emergency | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == Speed and Power Settings == | + | *'''Lines are cutting fuzzier and thicker than normal''' |

| + | |||

| + | #Make sure you ran the autofocus | ||

| + | #Try focusing the laser cutter by hand if you like '''and''' notify the fab lab team [mailto:fablab@makeict.org fablab@makeict.org] | ||

| + | |||

| + | *'''The laser doesn't fire''' | ||

| + | |||

| + | #Open the door and reclose (the door switch might be flakey) | ||

| + | #Check the door switch to make sure it is not broken (Close the lid. Look at the power supply. P0 on the power supply is an indicator of it being broken. A0 means it is ok. The power supply is in the left side of the cabinet behind the lower left door would indicate this is the case.) | ||

| + | |||

| + | *'''Edges of cut pieces are slanted, rather than straight.''' | ||

| + | |||

| + | ::The Laser is out of alignment and needs to be adjusted, notify the fab lab team [mailto:fablab@makeict.org fablab@makeict.org] | ||

| + | |||

| + | *'''Fumes are not venting well.''' | ||

| + | |||

| + | #Stop cutting | ||

| + | #Ventilation fan needs to be cleaned, notify the fab lab team [mailto:fablab@makeict.org fablab@makeict.org] | ||

| + | |||

| + | *'''The head hits the side of the machine. "Hard Limit Prot." error displayed on panel''' | ||

| + | |||

| + | ::Head position has been lost and the head has hit a limit switch. Reset the machine. If this continues to happen notify the fab lab team [mailto:fablab@makeict.org fablab@makeict.org] | ||

| + | |||

| + | *'''Can't run file, "Frame Slop" error displayed on panel.''' | ||

| + | |||

| + | ::The file is going to run off one of the edges of the machine. Change the starting position and/or resize your file so that it fits on the bed. | ||

| + | |||

| + | ==Speed and Power Settings== | ||

Every material and sometimes even every day is different, but here are some starting points: | Every material and sometimes even every day is different, but here are some starting points: | ||

| Line 105: | Line 142: | ||

!Power (%) | !Power (%) | ||

!Cut Rate (mm/s) | !Cut Rate (mm/s) | ||

| + | |- | ||

| + | |Masonite - 3/16" | ||

| + | |50% | ||

| + | |20 | ||

|- | |- | ||

|Plywood - 6mm | |Plywood - 6mm | ||

| Line 115: | Line 156: | ||

|- | |- | ||

|Engraving | |Engraving | ||

| − | |2- | + | |2-30% |

| − | |300 | + | |300-600 |

|} | |} | ||

| − | + | It is always highly recommended that you do some small test cuts/engraves before running your full design, especially if it is large or uses valuable material and/or you haven't lasered it before. This can save you a lot headaches. | |

| − | == Materials == | + | ==Materials== |

Cutting a bad material in the laser cutter can be dangerous. Only approved materials should be cut, and banned materials should never be placed in or even around the laser cutter. Cutting an unknown material risks bodily harm and damage to equipment/facilities. | Cutting a bad material in the laser cutter can be dangerous. Only approved materials should be cut, and banned materials should never be placed in or even around the laser cutter. Cutting an unknown material risks bodily harm and damage to equipment/facilities. | ||

| − | + | ===Approved materials=== | |

| − | |||

{| class="wikitable sortable" | {| class="wikitable sortable" | ||

|- | |- | ||

| − | ! Name !! Notes !! Warnings | + | !Name!!Notes!!Warnings |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Acrylic (aka Plexiglas, Lucite, PMMA)</div> || Cuts well, leaves a smooth polished edge. Higher powers can leave smoke/scorch marks along edges. Some people remove paper/plastic protection sheets before cutting. || | + | |<div style="background-color:#009900; color:#ffffff;">Acrylic (aka Plexiglas, Lucite, PMMA)</div>||Cuts well, leaves a smooth polished edge. Higher powers can leave smoke/scorch marks along edges. Some people remove paper/plastic protection sheets before cutting.|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Cardboard</div> || Cuts well, can catch fire || FIRE hazard! | + | |<div style="background-color:#009900; color:#ffffff;">Cardboard</div>||Cuts well, can catch fire||FIRE hazard! |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Ceramic</div> || '''Engraving only''' || '''Mirror surfaces can reflect the laser beam''' | + | |<div style="background-color:#009900; color:#ffffff;">Ceramic</div>||'''Engraving only'''||'''Mirror surfaces can reflect the laser beam''' |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Cloth (cotton, felt, hemp)</div> || Cuts easily || NO plastic coated or impregnated cloth! | + | |<div style="background-color:#009900; color:#ffffff;">Cloth (cotton, felt, hemp)</div>||Cuts easily||NO plastic coated or impregnated cloth! |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Corian</div> || | + | |<div style="background-color:#009900; color:#ffffff;">Corian</div>|| || |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Cork</div> || Cuts nicely, the quality of the cut depends on the thickness and quality of the cork. Engineered cork has a lot of glue in it, may not cut nicely. || | + | |<div style="background-color:#009900; color:#ffffff;">Cork</div>||Cuts nicely, the quality of the cut depends on the thickness and quality of the cork. Engineered cork has a lot of glue in it, may not cut nicely.|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Coroplast (corrugated plastic)</div> || Difficult to cut through cleanly, due to the ribs. Multiple passes are usually needed. || | + | |<div style="background-color:#009900; color:#ffffff;">Coroplast (corrugated plastic)</div>||Difficult to cut through cleanly, due to the ribs. Multiple passes are usually needed.|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Delrin</div> || Comes in a number of shore strengths ([http://www.matweb.com/reference/rockwell-hardness.aspx hardness]), the harder tends to work better. Great for gears! || | + | |<div style="background-color:#009900; color:#ffffff;">Delrin</div>||Comes in a number of shore strengths ([http://www.matweb.com/reference/rockwell-hardness.aspx hardness]), the harder tends to work better. Great for gears!|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Glass</div> || Has a sandblasted look, #009900 glass works best || '''Mirror surfaces can reflect the laser beam''' | + | |<div style="background-color:#009900; color:#ffffff;">Glass</div>||Has a sandblasted look, #009900 glass works best||'''Mirror surfaces can reflect the laser beam''' |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Leather, suede</div> || Leather is very hard to cut, can be if thinner than a belt thickness || | + | |<div style="background-color:#009900; color:#ffffff;">Leather, suede</div>||Leather is very hard to cut, can be if thinner than a belt thickness|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">MDF, engineered woods</div> || May experience a higher amount of charring when cut || | + | |<div style="background-color:#009900; color:#ffffff;">MDF, engineered woods</div>||May experience a higher amount of charring when cut|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Magnetic sheet</div> || Cuts easily || | + | |<div style="background-color:#009900; color:#ffffff;">Magnetic sheet</div>||Cuts easily|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Stone/Granite/Marble/etc.</div> || '''Engraving only''' || '''Mirror surfaces can reflect the laser beam''' | + | |<div style="background-color:#009900; color:#ffffff;">Stone/Granite/Marble/etc.</div>||'''Engraving only'''||'''Mirror surfaces can reflect the laser beam''' |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Matte Board</div> || | + | |<div style="background-color:#009900; color:#ffffff;">Matte Board</div>|| || |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Melamine</div> || | + | |<div style="background-color:#009900; color:#ffffff;">Melamine</div>|| || |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Mylar</div> || Works well if it's thin. Thick mylar has a tendency to warp, bubble, and curl || Gold coated mylar will not work | + | |<div style="background-color:#009900; color:#ffffff;">Mylar</div>||Works well if it's thin. Thick mylar has a tendency to warp, bubble, and curl||Gold coated mylar will not work |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Paper, card stock</div> || | + | |<div style="background-color:#009900; color:#ffffff;">Paper, card stock</div>|| || |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Plywood, composite woods</div> || Contain glue, and may not cut as well as solid wood || | + | |<div style="background-color:#009900; color:#ffffff;">Plywood, composite woods</div>||Contain glue, and may not cut as well as solid wood|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Pressboard</div> || | + | |<div style="background-color:#009900; color:#ffffff;">Pressboard</div>|| || |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">NON-CHLORINE Rubber</div> || '''DO NOT CUT''' unless the rubber compound has been tested || '''Beware chlorine-containing rubber!''' If you're not sure, assume you've got chlorinated rubber, and don't cut it. | + | |<div style="background-color:#009900; color:#ffffff;">NON-CHLORINE Rubber</div>||'''DO NOT CUT''' unless the rubber compound has been tested||'''Beware chlorine-containing rubber!''' If you're not sure, assume you've got chlorinated rubber, and don't cut it. |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Tile</div> || '''Engraving Only.''' || '''Mirror surfaces can reflect the laser beam''' | + | |<div style="background-color:#009900; color:#ffffff;">Tile</div>||'''Engraving Only.'''||'''Mirror surfaces can reflect the laser beam''' |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Wood</div> || Avoid oily/resinous woods || FIRE - Cutting oily woods, or very resinous woods can catch fire. | + | |<div style="background-color:#009900; color:#ffffff;">Wood</div>||Avoid oily/resinous woods||FIRE - Cutting oily woods, or very resinous woods can catch fire. |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Wood Veneer</div> || Contain glue, and may not cut as well as solid wood || | + | |<div style="background-color:#009900; color:#ffffff;">Wood Veneer</div>||Contain glue, and may not cut as well as solid wood|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Anodized Aluminum</div> ||'''Engraving only.''' Vaporizes the anodized layer away || | + | |<div style="background-color:#009900; color:#ffffff;">Anodized Aluminum</div>||'''Engraving only.''' Vaporizes the anodized layer away|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Bare Metals</div> || '''Engraving only.'''|| | + | |<div style="background-color:#009900; color:#ffffff;">Bare Metals</div>||'''Engraving only.'''|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Brass</div> || '''Engraving only.''' || | + | |<div style="background-color:#009900; color:#ffffff;">Brass</div>||'''Engraving only.'''|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Coated Metals</div> || '''Engraving only.''' Vaporizes the coating away || || | + | |<div style="background-color:#009900; color:#ffffff;">Coated Metals</div>||'''Engraving only.''' Vaporizes the coating away|| || |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Painted Metals</div> || '''Engraving only.''' Vaporizes the paint away || | + | |<div style="background-color:#009900; color:#ffffff;">Painted Metals</div>||'''Engraving only.''' Vaporizes the paint away|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Stainless Steel</div> || '''Engraving only.''' || | + | |<div style="background-color:#009900; color:#ffffff;">Stainless Steel</div>||'''Engraving only.'''|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">Titanium</div> ||'''Engraving only.''' || | + | |<div style="background-color:#009900; color:#ffffff;">Titanium</div>||'''Engraving only.'''|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">PolyPropylene Sheet</div> || '''NOT FOAM''' || | + | |<div style="background-color:#009900; color:#ffffff;">PolyPropylene Sheet</div>||'''NOT FOAM'''|| |

|- | |- | ||

| − | | <div style="background-color:#009900; color:#ffffff;">PolyStyrene Sheet</div> || '''NOT FOAM''' | + | |<div style="background-color:#009900; color:#ffffff;">PolyStyrene Sheet</div>||'''NOT FOAM'''||Tends to melt; avoid overheating. |

|} | |} | ||

| − | === Banned materials === | + | ===Banned materials=== |

| − | These materials should '''never''' be processed in the laser cutter. | + | These materials should '''never''' be processed in the laser cutter. This list is not exhaustive. |

{| class="wikitable sortable" | {| class="wikitable sortable" | ||

|- | |- | ||

| − | ! Name !! DANGER !! WARNING | + | !Name!!DANGER!!WARNING |

| + | |- | ||

| + | |<div style="background-color:#cc3333; color:#ffffff;">ABS (acrylonitrile butadiene styrene)</div>||Emits cyanide gas and tends to melt||ABS does not cut well in a laser cutter. It tends to melt rather than vaporize, and has a higher chance of catching on fire and leaving behind melted gooey deposits on the vector cutting grid. It also does not engrave well (again, tends to melt). | ||

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Chlorinated plastics (PVC/Poly Vinyl Chloride, vinyl/pleather/artificial leather)</div>||Emits pure chlorine gas when cut!||'''Don't ever cut this material''' as it will ruin the optics, cause the metal of the machine to corrode, and ruin the motion control system. Bubbles yellow, smokes alot, STINKS!!!!! |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Coated Carbon Fiber</div>||Emits noxious fumes||A mix of two materials. Thin carbon fiber mat can be cut, with some fraying - but not when coated |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Fiberglass</div>||Emits fumes||It's a mix of two materials that cant' be cut. Glass (etch, no cut) and epoxy resin (fumes) |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Galvanized metal</div>||Emits dangerous fumes||Zinc fumes are poisonous. Galvanized metal should never be super heated (so don't weld on it either). |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Metal</div>|| ||[https://en.wikipedia.org/wiki/Laser_cutting#Power_consumption Power needed for LASER to cut metal] |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Milk bottles/HDPE</div>||Catches fire and melts||It melts, gets gooey. DON'T. Someone has to clean the hex worktable. |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Mirrored surfaces</div>||Will not cut, reflects laser beam||Mirror surfaces can reflect the laser beam, damaging the cutter's interior components. Some mirrored materials can be placed reflective-side down and cut. |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">Polycarbonate/Lexan</div>||Cut very poorly, disbackground-color, catch fire||Polycarbonate is often found as flat, sheet material. The window of the laser cutter is made of Polycarbonate because polycarbonate strongly absorbs infrared radiation! This is the frequency of light the laser cutter uses to cut materials, so it is very ineffective at cutting polycarbonate. Polycarbonate is a poor choice for laser cutting. |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;"> | + | |<div style="background-color:#cc3333; color:#ffffff;">CDs, DVDs, Blu-rays, etc.</div>||Made of Polycarbonate.|| |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;">PolyPropylene Foam</div> || Catches fire || Like PolyStyrene, it melts, catches fire, and the melted drops continue to burn and turn into rock-hard drips and pebbles. | + | |<div style="background-color:#cc3333; color:#ffffff;">PolyPropylene Foam</div>||Catches fire||Like PolyStyrene, it melts, catches fire, and the melted drops continue to burn and turn into rock-hard drips and pebbles. |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;">PolyStyrene Foam</div> || Catches fire || Like PolyPropylene. It catches fire, it melts, and only thin pieces cut. '''This is the #1 material that causes laser fires!!!''' | + | |<div style="background-color:#cc3333; color:#ffffff;">PolyStyrene Foam</div>||Catches fire||Like PolyPropylene. It catches fire, it melts, and only thin pieces cut. '''This is the #1 material that causes laser fires!!!''' |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;">Pressure treated wood</div> || Emits dangerous fumes || Should never be burned -- not in your fireplace, and definitely not in our LASER | + | |<div style="background-color:#cc3333; color:#ffffff;">Pressure treated wood</div>||Emits dangerous fumes||Should never be burned -- not in your fireplace, and definitely not in our LASER |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;">Printed circuit board (FR4 and other material types)</div> || | + | |<div style="background-color:#cc3333; color:#ffffff;">Printed circuit board (FR4 and other material types)</div>|| || |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;">Unidentified plastics/rubbers </div> || | + | |<div style="background-color:#cc3333; color:#ffffff;">Unidentified plastics/rubbers </div>|| ||If you don't know what it is, don't put it in the LASER cutter |

|- | |- | ||

| − | | <div style="background-color:#cc3333; color:#ffffff;">Plastics from The Yard Store</div> || They do not properly identify their plastics || | + | |<div style="background-color:#cc3333; color:#ffffff;">Plastics from The Yard Store</div>||They do not properly identify their plastics|| |

| + | |- | ||

| + | |<div style="background-color:#cc3333; color:#ffffff;">Food</div>||Super gross, very unhealthy||If you plan to consume it, do not place it in the laser cutter. | ||

|- | |- | ||

|} | |} | ||

| − | == Other | + | ==Links & Other Resources== |

| − | * [http://makeict.org/lasercutter/ Reservation Calendar] | + | |

| − | + | *[http://makeict.org/lasercutter/ Laser Cutter Reservation Calendar] | |

| − | * [[Designing for the laser cutter] | + | *[[Designing for the laser cutter]] |

| − | + | *[https://drive.google.com/open?id=1HrwlAdZLoOOKw0-S6kRby9bPNl_fbgo6AaTRcu6Vac8 Laser Authorization Class Slides] | |

| − | * [https://drive.google.com/open?id=1HrwlAdZLoOOKw0-S6kRby9bPNl_fbgo6AaTRcu6Vac8 Laser Authorization Class Slides] | + | **[https://docs.google.com/document/d/1vCWqg8ivAJMtIyzjX36WSnwlWHAV-vaacEZteQVkDPw/edit?usp=sharing Laser Authorization Class Quiz] |

| − | * [https:// | + | **[https://docs.google.com/document/d/17gjllXoLKLQtmsogXGy8iKY1f2_WG6318IYX68pIxX0/edit#heading=h.81m3irbp3xls Google Doc: Your First Laser Cutter Project] |

| − | * [https://docs.google.com/document/d/17gjllXoLKLQtmsogXGy8iKY1f2_WG6318IYX68pIxX0/edit#heading=h.81m3irbp3xls Google Doc: Your First Laser Cutter Project] | + | **[https://drive.google.com/open?id=0B9tsLcc_rWFAS01sWllsUU5aUDQ SVG Files For Laser Classes (Google Drive)] |

| − | * [https://drive.google.com/open?id=13BWPzsnGROKjk1pFY5FkqugTAUehY3bJHdTYfOV56gc Rotary Class Slides] | + | *[https://drive.google.com/open?id=13BWPzsnGROKjk1pFY5FkqugTAUehY3bJHdTYfOV56gc Rotary Class Slides] |

| + | *[http://www.thingiverse.com/tag:lasercut Thingiverse Laser Cut projects] | ||

| + | *[http://makezine.com/2011/09/22/identifying-unknown-plastics/ Identifying Unknown Plastics by Make Magazine] | ||

| + | *[https://en.wikipedia.org/wiki/Beilstein_test Beilstein test] | ||

| + | *[https://vimeo.com/1615418 Polymer Identification (video) by Burnination] | ||

| + | *[http://www.chymist.com/Polymer%20Identification.pdf Polymer Identification (PDF) by David A. Katz] | ||

| + | *[http://www.nclark.net/Density_Column.pdf Density Column Using Recyclable Plastics] | ||

| − | + | [[Category:Laser cutter]] | |

| − | + | [[Category:Fablab]] | |

| − | + | [[Category:Equipment]] | |

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 10:25, 11 March 2024

| Rabbit QX-80-1290 Laser engraving/cutting machine | |

|---|---|

Rabbit Laser Cutter | |

| Technical Specifications | |

| Bed Size | 1200 x 900 mm (47.2 x 35.4 inches) |

| LASER Power | 80W |

| LASER Type | Sealed CO2 laser tube |

| Max Bed Height | ~10 inches |

| Max Cut Speed | 300 mm/s |

| Max Engrave Speed | 600 mm/s |

| Max Engrave Resolution | 1000 DPI |

| Additional Information | |

| User Manual | RL-80-1290_User_Manual.pdf |

| Website | Rabbit QX-80-1290 Product Page |

The Laser cutter cuts or engraves digital designs on a variety of materials. Laser cutting is a great way to rapidly prototype projects.

An authorization workshop, hosted by an approved instructor, is required of all members before using the laser cutter. Workshops are posted on the calendar. Peer authorization is not an approved path for use of the laser cutter.

Interfacing with the laser cutter is performed with Lightburn.

The laser cutter does require regular cleaning and alignment. This is to be performed by trained volunteers only.

NOTE: The focal length of the lens in Luigi is 63.5mm and not 50.8mm like Mario. The longer focal length is better for cutting, but not as good for engraving.

Contents

Usage

Safety

Fire Safety

Laser cutters pose a fire hazard. A high intensity beam of laser light can produce extremely high temperatures as it comes into contact with the materials it is engraving, marking, or cutting. When using the laser cutter, remember:

- You may only use the laser cutter if you have been officially authorized according to the machine access policy

- Never leave the laser cutter unattended while it was powered on (even if it is not firing)

- Never cut materials that you don't know are safe

- Never override laser cutter safeties and switches

- Know what to do if a fire happens

- Move the head out of the way, if it's small.

- Hint: Hit the big, red, emergency stop button. This will shutdown the laser and the air supply

- A Carbon Dioxide (CO2) fire extinguisher is located next to the laser cutter

- Verify it is out and then:

- Place a note that a fire occurred and the machine is out of service.

- Post on the forum about it, or send an email to fablab@makeict.org

- Someone from the laser group will check the machine, clean as necessary, and put it back into service.

Eye Safety

The laser is encased and will not fire unless the doors are shut. Do not bypass any safety lockouts or open panels without consulting the fablab lead first. Lasers can cause serious eye damage, even indirectly through scattered energy.

Air Safety

Many materials give off toxic fumes when cut. Do not cut unapproved, unknown or banned materials on the laser cutter. See the list of approved/banned materials on this wiki

Workflow

- Create your design on another computer

- LightBurn (detailed steps)

- Import your file into Lightburn

- Set up layers

- Fill (start with 100mm/s speed, 20% power)

- Line (start with 20mm/s speed, 50% power)

- Re-order layers so the outermost path is at the end

- Verify design size

- Preview laser paths (TV button)

- Set job origin based on desired laser head starting point (green dot)

- Turn on the machine

- Turn on the laser cutter using your badge and the green button

- Make sure the air compressor, blower fans, and chiller are on

- Wait for homing sequence to complete

- Lower the bed (z button, then arrows) until material will easily fit under the head

- Load material onto laser cutter bed

- Jog head to center of media using control panel (z/esc to switch modes)

- Raise table until material is 7-8mm below head

- Jog head to desired starting point

- Return to Lightburn

- Press "Frame" to outline your job and check that it fits

- Gently lower lid until closed

- In Lightburn, press "start" (play button)

- Do not leave laser cutter unattended

- After cut is finished allow ~30 seconds before opening to vent smoke/fumes

When Finished

- Home the head

- Remove media and clear debris

- Power off

Rotary Axis

If you are using the rotary axis, refer to this page

Troubleshooting Guide

- Bed only travels downwards

- Wiggle the probe and make sure its not jammed

- Check to see if the upper z-limit switch is stuck

- If none of these work, notify the fab lab team fablab@makeict.org

- Head does not home properly, move very slowly in Y axis

- The machine is probably in rotary mode

- Turn the machine on, hit 'esc' on the control panel to cancel homing, and disable the 'Enable rotary' setting in the control box with the 'Start' and 'Stop' buttons

- Machine won't turn on

- If the lights don't turn change when you scan your badge, unplug machine power for 5 seconds and re-plug

- If the light turns red when you scan your badge, you are not authorized for the lasers

- If the light turns green but the machine does not turn on, make sure the power switch is pressed and the emergency stop is not pressed

- The emergency

- Lines are cutting fuzzier and thicker than normal

- Make sure you ran the autofocus

- Try focusing the laser cutter by hand if you like and notify the fab lab team fablab@makeict.org

- The laser doesn't fire

- Open the door and reclose (the door switch might be flakey)

- Check the door switch to make sure it is not broken (Close the lid. Look at the power supply. P0 on the power supply is an indicator of it being broken. A0 means it is ok. The power supply is in the left side of the cabinet behind the lower left door would indicate this is the case.)

- Edges of cut pieces are slanted, rather than straight.

- The Laser is out of alignment and needs to be adjusted, notify the fab lab team fablab@makeict.org

- Fumes are not venting well.

- Stop cutting

- Ventilation fan needs to be cleaned, notify the fab lab team fablab@makeict.org

- The head hits the side of the machine. "Hard Limit Prot." error displayed on panel

- Head position has been lost and the head has hit a limit switch. Reset the machine. If this continues to happen notify the fab lab team fablab@makeict.org

- Can't run file, "Frame Slop" error displayed on panel.

- The file is going to run off one of the edges of the machine. Change the starting position and/or resize your file so that it fits on the bed.

Speed and Power Settings

Every material and sometimes even every day is different, but here are some starting points:

| Material | Power (%) | Cut Rate (mm/s) |

|---|---|---|

| Masonite - 3/16" | 50% | 20 |

| Plywood - 6mm | 50% | 15 |

| Cardboard | 50% | 50 |

| Engraving | 2-30% | 300-600 |

It is always highly recommended that you do some small test cuts/engraves before running your full design, especially if it is large or uses valuable material and/or you haven't lasered it before. This can save you a lot headaches.

Materials

Cutting a bad material in the laser cutter can be dangerous. Only approved materials should be cut, and banned materials should never be placed in or even around the laser cutter. Cutting an unknown material risks bodily harm and damage to equipment/facilities.

Approved materials

| Name | Notes | Warnings | |

|---|---|---|---|

Acrylic (aka Plexiglas, Lucite, PMMA) |

Cuts well, leaves a smooth polished edge. Higher powers can leave smoke/scorch marks along edges. Some people remove paper/plastic protection sheets before cutting. | ||

Cardboard |

Cuts well, can catch fire | FIRE hazard! | |

Ceramic |

Engraving only | Mirror surfaces can reflect the laser beam | |

Cloth (cotton, felt, hemp) |

Cuts easily | NO plastic coated or impregnated cloth! | |

Corian |

|||

Cork |

Cuts nicely, the quality of the cut depends on the thickness and quality of the cork. Engineered cork has a lot of glue in it, may not cut nicely. | ||

Coroplast (corrugated plastic) |

Difficult to cut through cleanly, due to the ribs. Multiple passes are usually needed. | ||

Delrin |

Comes in a number of shore strengths (hardness), the harder tends to work better. Great for gears! | ||

Glass |

Has a sandblasted look, #009900 glass works best | Mirror surfaces can reflect the laser beam | |

Leather, suede |

Leather is very hard to cut, can be if thinner than a belt thickness | ||

MDF, engineered woods |

May experience a higher amount of charring when cut | ||

Magnetic sheet |

Cuts easily | ||

Stone/Granite/Marble/etc. |

Engraving only | Mirror surfaces can reflect the laser beam | |

Matte Board |

|||

Melamine |

|||

Mylar |

Works well if it's thin. Thick mylar has a tendency to warp, bubble, and curl | Gold coated mylar will not work | |

Paper, card stock |

|||

Plywood, composite woods |

Contain glue, and may not cut as well as solid wood | ||

Pressboard |

|||

NON-CHLORINE Rubber |

DO NOT CUT unless the rubber compound has been tested | Beware chlorine-containing rubber! If you're not sure, assume you've got chlorinated rubber, and don't cut it. | |

Tile |

Engraving Only. | Mirror surfaces can reflect the laser beam | |

Wood |

Avoid oily/resinous woods | FIRE - Cutting oily woods, or very resinous woods can catch fire. | |

Wood Veneer |

Contain glue, and may not cut as well as solid wood | ||

Anodized Aluminum |

Engraving only. Vaporizes the anodized layer away | ||

Bare Metals |

Engraving only. | ||

Brass |

Engraving only. | ||

Coated Metals |

Engraving only. Vaporizes the coating away | ||

Painted Metals |

Engraving only. Vaporizes the paint away | ||

Stainless Steel |

Engraving only. | ||

Titanium |

Engraving only. | ||

PolyPropylene Sheet |

NOT FOAM | ||

PolyStyrene Sheet |

NOT FOAM | Tends to melt; avoid overheating. |

Banned materials

These materials should never be processed in the laser cutter. This list is not exhaustive.

| Name | DANGER | WARNING |

|---|---|---|

ABS (acrylonitrile butadiene styrene) |

Emits cyanide gas and tends to melt | ABS does not cut well in a laser cutter. It tends to melt rather than vaporize, and has a higher chance of catching on fire and leaving behind melted gooey deposits on the vector cutting grid. It also does not engrave well (again, tends to melt). |

Chlorinated plastics (PVC/Poly Vinyl Chloride, vinyl/pleather/artificial leather) |

Emits pure chlorine gas when cut! | Don't ever cut this material as it will ruin the optics, cause the metal of the machine to corrode, and ruin the motion control system. Bubbles yellow, smokes alot, STINKS!!!!! |

Coated Carbon Fiber |

Emits noxious fumes | A mix of two materials. Thin carbon fiber mat can be cut, with some fraying - but not when coated |

Fiberglass |

Emits fumes | It's a mix of two materials that cant' be cut. Glass (etch, no cut) and epoxy resin (fumes) |

Galvanized metal |

Emits dangerous fumes | Zinc fumes are poisonous. Galvanized metal should never be super heated (so don't weld on it either). |

Metal |

Power needed for LASER to cut metal | |

Milk bottles/HDPE |

Catches fire and melts | It melts, gets gooey. DON'T. Someone has to clean the hex worktable. |

Mirrored surfaces |

Will not cut, reflects laser beam | Mirror surfaces can reflect the laser beam, damaging the cutter's interior components. Some mirrored materials can be placed reflective-side down and cut. |

Polycarbonate/Lexan |

Cut very poorly, disbackground-color, catch fire | Polycarbonate is often found as flat, sheet material. The window of the laser cutter is made of Polycarbonate because polycarbonate strongly absorbs infrared radiation! This is the frequency of light the laser cutter uses to cut materials, so it is very ineffective at cutting polycarbonate. Polycarbonate is a poor choice for laser cutting. |

CDs, DVDs, Blu-rays, etc. |

Made of Polycarbonate. | |

PolyPropylene Foam |

Catches fire | Like PolyStyrene, it melts, catches fire, and the melted drops continue to burn and turn into rock-hard drips and pebbles. |

PolyStyrene Foam |

Catches fire | Like PolyPropylene. It catches fire, it melts, and only thin pieces cut. This is the #1 material that causes laser fires!!! |

Pressure treated wood |

Emits dangerous fumes | Should never be burned -- not in your fireplace, and definitely not in our LASER |

Printed circuit board (FR4 and other material types) |

||

Unidentified plastics/rubbers |

If you don't know what it is, don't put it in the LASER cutter | |

Plastics from The Yard Store |

They do not properly identify their plastics | |

Food |

Super gross, very unhealthy | If you plan to consume it, do not place it in the laser cutter. |

Links & Other Resources

- Laser Cutter Reservation Calendar

- Designing for the laser cutter

- Laser Authorization Class Slides

- Rotary Class Slides

- Thingiverse Laser Cut projects

- Identifying Unknown Plastics by Make Magazine

- Beilstein test

- Polymer Identification (video) by Burnination

- Polymer Identification (PDF) by David A. Katz

- Density Column Using Recyclable Plastics