Difference between revisions of "Metalshop Area"

From MakeICT Wiki

Jump to navigationJump to searchMike Hutton (talk | contribs) |

Mike Hutton (talk | contribs) |

||

| Line 87: | Line 87: | ||

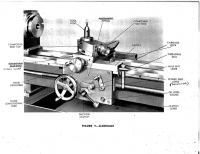

| [[File:Anatomy_of_Logan_Lathe.png|200px]] || 12"x 35" Metal Gear Head Lathe|| Logan-Powermatic || 2557TH|| 220 || Working|| ?? ||[[File:Logan_manual.pdf|manual]] | | [[File:Anatomy_of_Logan_Lathe.png|200px]] || 12"x 35" Metal Gear Head Lathe|| Logan-Powermatic || 2557TH|| 220 || Working|| ?? ||[[File:Logan_manual.pdf|manual]] | ||

|- | |- | ||

| − | |||

| [[File:Craftsman lathe.jpg|200px]] || 12" Metal Lathe|| Craftsman || 101.28990|| 110 || Working|| ?? ||[[File:Craftsman Lathe manual.pdf|manual]] | | [[File:Craftsman lathe.jpg|200px]] || 12" Metal Lathe|| Craftsman || 101.28990|| 110 || Working|| ?? ||[[File:Craftsman Lathe manual.pdf|manual]] | ||

|- | |- | ||

| Line 98: | Line 97: | ||

| [[File:WELDING HELMET.jpg|200px]] || Welding Helmet || Chicago Electric || 91214 || solar || Working || [[User:Gavin Rondeau|Gavin Rondeau]] || [[File:WELDING HELMET.pdf|manual]] | | [[File:WELDING HELMET.jpg|200px]] || Welding Helmet || Chicago Electric || 91214 || solar || Working || [[User:Gavin Rondeau|Gavin Rondeau]] || [[File:WELDING HELMET.pdf|manual]] | ||

|- | |- | ||

| − | | [[File:Ingersoll_Compressor.jpg|200px]] || [[media:IR SS5L5 manual.pdf|5HP 60 gal Compressor]] || Ingersoll Rand || SS5L5 || 220 || Operational || [[User:Jeremiah | + | | [[File:Ingersoll_Compressor.jpg|200px]] || [[media:IR SS5L5 manual.pdf|5HP 60 gal Compressor]] || Ingersoll Rand || SS5L5 || 220 || Operational || [[User:Jeremiah Burian|Jeremiah Burian]] |

|- | |- | ||

| [[File: DWE402G.jpg|200px]] || 4-1/2” Paddle Angle Grinder || DeWalt || DWE402G || 110V || Working || [[User:Jeff Eck|Jeff Eck]] || [[media: DWE402G _manual.pdf |manual]] | | [[File: DWE402G.jpg|200px]] || 4-1/2” Paddle Angle Grinder || DeWalt || DWE402G || 110V || Working || [[User:Jeff Eck|Jeff Eck]] || [[media: DWE402G _manual.pdf |manual]] | ||

|- | |- | ||

| − | | [[File:ANGLE GRINDER.jpg|200px]] || 4.5" Angle Grinder || Chicago Electric || 91223 || 110 || Working || [[User: | + | | [[File:ANGLE GRINDER.jpg|200px]] || 4.5" Angle Grinder || Chicago Electric || 91223 || 110 || Working || [[User:Jeremiah Burian|Jeremiah Burian]] ||[[File:ANGLE_GRINDER.pdf|manual]] |

|- | |- | ||

| − | | [[File:tumbler.jpg|200px]] || 18 Lb Vibratory Tumbler || Chicago Electric || 96923 || 110 || Working || [[User: | + | | [[File:tumbler.jpg|200px]] || 18 Lb Vibratory Tumbler || Chicago Electric || 96923 || 110 || Working || [[User:Jeremiah Burian|Jeremiah Burian]] ||[[File:tumbler_manual.pdf|manual]] |

|- | |- | ||

| − | | [[File:SHEAR-BRAKE-ROLLER.jpg|200px]] || Combo Shear/Brake/Roller || Central Machinery || 5907 || Working || Working || [[User: | + | | [[File:SHEAR-BRAKE-ROLLER.jpg|200px]] || Combo Shear/Brake/Roller || Central Machinery || 5907 || Working || Working || [[User:Jeremiah Burian|Jeremiah Burian]] || |

[[File:SHEAR-BRAKE-ROLLER.pdf|manual]] | [[File:SHEAR-BRAKE-ROLLER.pdf|manual]] | ||

|- | |- | ||

| − | | [[File:BANDSAW.jpg|200px]] || Horizontal/Vertical Metal Cutting Band Saw || Central Machinery || 93762 || 110 || Working || [[User: | + | | [[File:BANDSAW.jpg|200px]] || Horizontal/Vertical Metal Cutting Band Saw || Central Machinery || 93762 || 110 || Working || [[User:Jeremiah Burian|Jeremiah Burian]] || [[File:LAYDOWN BANDSAW.pdf]] |

|- | |- | ||

| − | | [[File:Jet_JBS-14MW_photo.jpg|200px]] || 14" Vertical Metal/Wood Cutting Band Saw || Jet || JBS-14MW || 110 || Working || [[User: | + | | [[File:Jet_JBS-14MW_photo.jpg|200px]] || 14" Vertical Metal/Wood Cutting Band Saw || Jet || JBS-14MW || 110 || Working || [[User:Jeremiah Burian|Jeremiah Burian]] || [[File:Jet_JBS-14MW_manual.pdf]] |

|- | |- | ||

| − | | [[File:BANDFILE.jpg|200px]] || 1/2" Bandfile Belt Sander || Chicago Electric || 92158 || 110 || Working || [[User: | + | | [[File:BANDFILE.jpg|200px]] || 1/2" Bandfile Belt Sander || Chicago Electric || 92158 || 110 || Working || [[User:Jeremiah Burian|Jeremiah Burian]] || [[File:BANDFILE.pdf]] |

|- | |- | ||

| − | | [[File:BAR AND ROD BENDER.jpg|200px]] || Bar and Rod Bender || Central Machinery || 38471 || Elbow grease || To Setup || [[User: | + | | [[File:BAR AND ROD BENDER.jpg|200px]] || Bar and Rod Bender || Central Machinery || 38471 || Elbow grease || To Setup || [[User:Jeremiah Burian|Jeremiah Burian]] || [[File:BAR AND ROD BENDER.pdf]] |

|- | |- | ||

| − | | [[File:tube roller.jpg|200px]] || Tubing Roller || Pittsburgh || 99736 || Working || Setup || [[User: | + | | [[File:tube roller.jpg|200px]] || Tubing Roller || Pittsburgh || 99736 || Working || Setup || [[User:Jeremiah Burian|Jeremiah Burian]] || [[File:99736 tube roller manual.pdf]] |

|- | |- | ||

| − | | [[File:20ton press.jpg|200px]] || 20 Ton Hydraulic Press || Central Machinery || 20 Ton || Working || Setup || [[User: | + | | [[File:20ton press.jpg|200px]] || 20 Ton Hydraulic Press || Central Machinery || 20 Ton || Working || Setup || [[User:Jeremiah Burian|Jeremiah Burian]] || |

|- | |- | ||

| − | | [[File:Lift Table.jpg|200px]] || 1000lb Hydraulic Lift Table || Central Machinery || 1000 lbs, 34" max height || Working || Setup || [[User: | + | | [[File:Lift Table.jpg|200px]] || 1000lb Hydraulic Lift Table || Central Machinery || 1000 lbs, 34" max height || Working || Setup || [[User:Jeremiah Burian|Jeremiah Burian]] || [[File:Lift table manual.pdf]] |

|- | |- | ||

| − | | [[File:Foldable Shop Crane.jpg|200px]] || Foldable 2 Ton Shop Crane (Cherry Picker) || Pittsburgh || 2 Ton || Working || Setup || [[User: | + | | [[File:Foldable Shop Crane.jpg|200px]] || Foldable 2 Ton Shop Crane (Cherry Picker) || Pittsburgh || 2 Ton || Working || Setup || [[User:Jeremiah Burian|Jeremiah Burian]] || [[File:Shop Crane manual.pdf]] |

|- | |- | ||

| − | | [[File:Johnson forge.jpg|200px]] || 120K BTU/hr Gas Forge|| Johnson Forge || 120K BTU || Needs converted to NG || Setup for propane|| [[User: | + | | [[File:Johnson forge.jpg|200px]] || 120K BTU/hr Gas Forge|| Johnson Forge || 120K BTU || Needs converted to NG || Setup for propane|| [[User:Jeremiah Burian|Jeremiah Burian]] || |

|- | |- | ||

| − | | [[File:ANVIL.jpg|200px]] || Anvil || Trenton || Made in 1900 || On the Stump || Setup || [[User: | + | | [[File:ANVIL.jpg|200px]] || Anvil || Trenton || Made in 1900 || On the Stump || Setup || [[User:Jeremiah Burian|Jeremiah Burian]] || |

|- | |- | ||

|}</onlyinclude> | |}</onlyinclude> | ||

Revision as of 12:22, 26 February 2017

Contents

General Information

MakeICT's metal shop is an open 1200 sq ft area dedicated to metal working with a shared space for bicycle repair.

Jeremiah Burian is the Metalshop Lead

MetalShop Wish List

A list of equipment or tools that the metalshop would like to obtain. If you would like to donate one of these tools please contact the Metalshop Lead before dropping the tools or equipment off.

- 2x72 Belt Grinder

- 12 inch Disc grinder / belt sander combo

- Tubing notcher

- Cordless power tool set drill,sawzall,impact

- Pneumatic nibblers and shears

- Manual mill endmills and bits

Machine Access Policy

- Use of the Metal Shop requires attendance in the area-specific safety class. Completion of the safety class will grant access to the area and use of the basic tools.

- Advanced tools require demonstration of safe and correct operation to an approved authorizer, as listed on the Wiki, or attendance in an instructional class. These tools are: Welders, Plasma Cutter, Forge, Lathes, Manual Mill, CNC Plasma, Powder coating equipment, Oxy / Acetylene torch, and the Tormach CNC Mill.

Approved by the board on January 18, 2018

General Shop Safety

- Do not use any equipment you are not comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help.

- Do not use any machine that is not in good working order. unplug The equipment,leave a note on the machine and notify the metalshop Lead-Jeremiah Burian.

- Always check tools prior to use.

- Wear safety glasses at all times when tools are in use in the shop area.

- Ear protection is recommended

- No open-toed shoes or loose clothing

- Remove objects on hands and wrists

- Remove dangly necklaces and earrings

- Restrain long hair to prevent entanglement

- Do not leave machines running unattended.

- Never talk to or disturb anyone operating power tools, forge or welding equipment. If you must talk to an operator wait until the operator finishes the operation.

- Be aware of the work going on around you.

- Wear proper PPE (personal protective equipment) Safety glasses welding sleeves, grinding shields etc.

Metalshop Safety

- You are responsible for cleaning your machines, your work space, and putting all tools away after use. Scrap metal should be placed in designated locations. Use vacuums or hand brushes to clean machinery.

- Users who consistently fail in their clean-up responsibilities may be denied shop access.

- Make sure machines are in the “off” position and motion has stopped, before leaving them after use.

- Make sure all gas cylinders are in the off position while not in use.

- All safety guards must be kept in place while operating equipment. If a guard or safety device is an impediment to safe operation of a machine - ask for help.

- Use equipment only for its intended use.

- If you have made an adjustment to a piece of equipment, return it to its normal position after you are done.

- All guests are the responsibility of the member. Guests are NOT allowed to use equipment. Children under 8 years old are not allowed for safety.

Machine shop Specific Safety

- This includes all mills and lathes in the metalshop.

- Lead or authorized peer certification is required to operate this equipment. This can be as easy as showing the Lead or peer the proper use of said equipment and describing experience.

- Due to the high level of technical understanding and cost of the Tormach CNC mill, extensive training will be required before use.

Welding shop Specific Safety

- Use the proper face shield when grinding and a welding helmet when welding.

- closed-toed shoes.

- Wear the appropriate glove while welding.

- We suggest you wear ear protection to prevent sparks from entering your ear canal.

- NEVER weld on or near anything that's been cleaned with a chlorinated hydrocarbon like brake-cleaner. When combined with UV light, chlorinated hydrocarbons can create phosgene gas, which can cause serious injury or death. Ventilation will not prevent poisoning.

- No galvanized (zinc plated) material should be welded without removal of the galvanized coating near the weld zone to protect from poison gas release.

Fire

- Make sure the hot work area is free from all flammable materials such as flammable liquids, paper, etc. Do not wear clothing or gloves that have been exposed to flammable liquids.

Burns

- Welded metal will remain hot for several minutes after it is welded.

UV Burns

- The light emitted from a weld arc is brighter than the sun. Do not look at the arc without wearing a full-faced welding mask with a shade 9 or darker filter plate.

Compressed Gas Cylinders

- Argon and CO2 are inert, nontoxic gases normally present in the atmosphere. However, if allowed to fill an enclosed area these gases can fully displace breathable air, causing asphyxiation and death. Greater potential danger is the valve being knocked off the cylinder, turning it into a rocket powerful enough to severely injure or kill people and damage equipment and the building itself.

- The following guidelines must be followed at all times:

- Storing

- Cylinders must ALWAYS remain upright and NEVER be placed horizontally.

- Cylinders must be secured with a non-combustible material (metal) to an immovable object to prevent them from falling.

- Moving

- Cylinders must be securely capped.

- Storing

Equipment List

| Picture | What | Manufacturer | Model | Power | Status | Expert | How To |

|---|---|---|---|---|---|---|---|

|

4 Axis 34" x 9.5" Tormach CNC Mill | Tormach | PCNC 1100 | 220 | Working | Curt Gridley | [manual] |

|

12"x 35" Metal Gear Head Lathe | Logan-Powermatic | 2557TH | 220 | Working | ?? | File:Logan manual.pdf |

|

12" Metal Lathe | Craftsman | 101.28990 | 110 | Working | ?? | File:Craftsman Lathe manual.pdf |

|

8"x29" Mill Drill | Enco | GL-30B | 110 | Working | ?? | File:RF-30 manual.pdf |

|

MIG Autoset Welder | Miller | Millermatic 211 Autoset | 220 | Working | Jeff Eck | File:Miller211 manual.pdf |

|

Plasma Cutter | Hypertherm | 30 XP | 220 | Working | Jeff Eck | File:Hypertherm30XP manual.pdf |

|

Welding Helmet | Chicago Electric | 91214 | solar | Working | Gavin Rondeau | File:WELDING HELMET.pdf |

|

5HP 60 gal Compressor | Ingersoll Rand | SS5L5 | 220 | Operational | Jeremiah Burian | |

|

4-1/2” Paddle Angle Grinder | DeWalt | DWE402G | 110V | Working | Jeff Eck | manual |

|

4.5" Angle Grinder | Chicago Electric | 91223 | 110 | Working | Jeremiah Burian | File:ANGLE GRINDER.pdf |

|

18 Lb Vibratory Tumbler | Chicago Electric | 96923 | 110 | Working | Jeremiah Burian | File:Tumbler manual.pdf |

|

Combo Shear/Brake/Roller | Central Machinery | 5907 | Working | Working | Jeremiah Burian | |

|

Horizontal/Vertical Metal Cutting Band Saw | Central Machinery | 93762 | 110 | Working | Jeremiah Burian | File:LAYDOWN BANDSAW.pdf |

|

14" Vertical Metal/Wood Cutting Band Saw | Jet | JBS-14MW | 110 | Working | Jeremiah Burian | File:Jet JBS-14MW manual.pdf |

|

1/2" Bandfile Belt Sander | Chicago Electric | 92158 | 110 | Working | Jeremiah Burian | File:BANDFILE.pdf |

|

Bar and Rod Bender | Central Machinery | 38471 | Elbow grease | To Setup | Jeremiah Burian | File:BAR AND ROD BENDER.pdf |

|

Tubing Roller | Pittsburgh | 99736 | Working | Setup | Jeremiah Burian | File:99736 tube roller manual.pdf |

|

20 Ton Hydraulic Press | Central Machinery | 20 Ton | Working | Setup | Jeremiah Burian | |

|

1000lb Hydraulic Lift Table | Central Machinery | 1000 lbs, 34" max height | Working | Setup | Jeremiah Burian | File:Lift table manual.pdf |

|

Foldable 2 Ton Shop Crane (Cherry Picker) | Pittsburgh | 2 Ton | Working | Setup | Jeremiah Burian | File:Shop Crane manual.pdf |

|

120K BTU/hr Gas Forge | Johnson Forge | 120K BTU | Needs converted to NG | Setup for propane | Jeremiah Burian | |

|

Anvil | Trenton | Made in 1900 | On the Stump | Setup | Jeremiah Burian |

MetalShop Classes

Safety Class

- This is a free course for members

- This class covers the basic safety knowledge to allow members to use the basic metal working tools and grants access to the basic equipment.

- It does NOT teach members how to properly use these tools.

- It does NOT unlock machining tools, Tormach, mill or lathe.

- It does NOT unlock Forge or smelting equipment.

- It does not unlock the welders or Plasma cutter.

MIG Welding Class

- Never welded before? Want to improve your welding abilities? Here you go!

- Class starts with some short videos and some classroom time, then moves out to the metal shop for an equipment overview and demonstration. After that, every person will have a chance to do some welding with an experienced welder coaching you. There will be a fee for this class.

Plasma Cutting Class

- There will be a fee for this class.

- Short class time to learn some basics

- This class will cover cutting steel with the plasma cutter and what settings to use for what thickness of metal. Proper tip selection and changing. It will also have a hands on session where everyone will get a chance to use the cutter on different thickness materials.

Milling Class

- We are currently looking for an instructor for this class, if you are interested in teaching this class contact the metalshop Lead

Lathe Class

- We are currently looking for an instructor for this class, if you are interested in teaching this class contact the metalshop Lead

Bicycle Maintenance

- We are currently looking for an instructor for this class, if you are interested in teaching this class contact the metalshop Lead

Basic Forge Techniques

- We are currently looking for an instructor for this class, if you are interested in teaching this class contact the metalshop Lead