Difference between revisions of "CNC Plasma Cutter"

(→Fusion 360: test) |

|||

| Line 55: | Line 55: | ||

The first thing you want to do is to grab the Post-Processor. This will ensure that your G-Code matches what our table needs to operate. This really just replaces the M3 with a pierce probe and adds an M5 to stop the torch. | The first thing you want to do is to grab the Post-Processor. This will ensure that your G-Code matches what our table needs to operate. This really just replaces the M3 with a pierce probe and adds an M5 to stop the torch. | ||

| − | *[https://drive.google.com/file/d/ | + | *[https://drive.google.com/file/d/1Q4T7HNoS423AGpF3RqtHjXEXta4RsMse/view?usp=share_link Post-Processor] |

| Line 153: | Line 153: | ||

=Linuxcnc= | =Linuxcnc= | ||

| − | *notes - at this time the THC and the Ohmic touchoff are not wired up. make sure they are not selected. Will post here when that changes along with a tutorial on using them. | + | *notes - at this time the THC and the Ohmic touchoff are not wired up. make sure they are not selected. Will post here when that changes along with a tutorial on using them. |

| − | * Turn on Computer & Table power. | + | *Turn on Computer & Table power. |

| − | * DO NOT TURN ON PLASMA CUTTER! | + | *DO NOT TURN ON PLASMA CUTTER! |

| − | * Login | + | *Login |

| − | ** PC Login: plasma | + | **PC Login: plasma |

| − | ** PC Password: linuxcnc | + | **PC Password: linuxcnc |

| − | * Open Linuxcnc from the desktop. | + | *Open Linuxcnc from the desktop. |

| − | * Click power button (Top Middle of the Screen), if the power button is disabled/greyed out make sure the estop isnt pressed | + | *Click power button (Top Middle of the Screen), if the power button is disabled/greyed out make sure the estop isnt pressed |

| − | * Click the "Home All" button in the Lower Right. | + | *Click the "Home All" button in the Lower Right. |

| − | * [[File:HomeAll.png]] | + | *[[File:HomeAll.png]] |

| − | * Move the machine with the arrow keys on the keyboard or with the GUI to the material and position it according to your fusion 360 setup file (e.g. for most files this is the lower left portion of the material) | + | *Move the machine with the arrow keys on the keyboard or with the GUI to the material and position it according to your fusion 360 setup file (e.g. for most files this is the lower left portion of the material) |

| − | * Click open touch off button note only the x and y need to be touched off | + | *Click open touch off button note only the x and y need to be touched off |

| − | * [[File:Touchoff.png]] | + | *[[File:Touchoff.png]] |

| − | * Click the file button to select your file | + | *Click the file button to select your file |

| − | * [[File:File Button.png]] | + | *[[File:File Button.png]] |

| − | * Choose the correct .ngc file. | + | *Choose the correct .ngc file. |

| − | * Double check size measurements on screen to material size.. | + | *Double check size measurements on screen to material size.. |

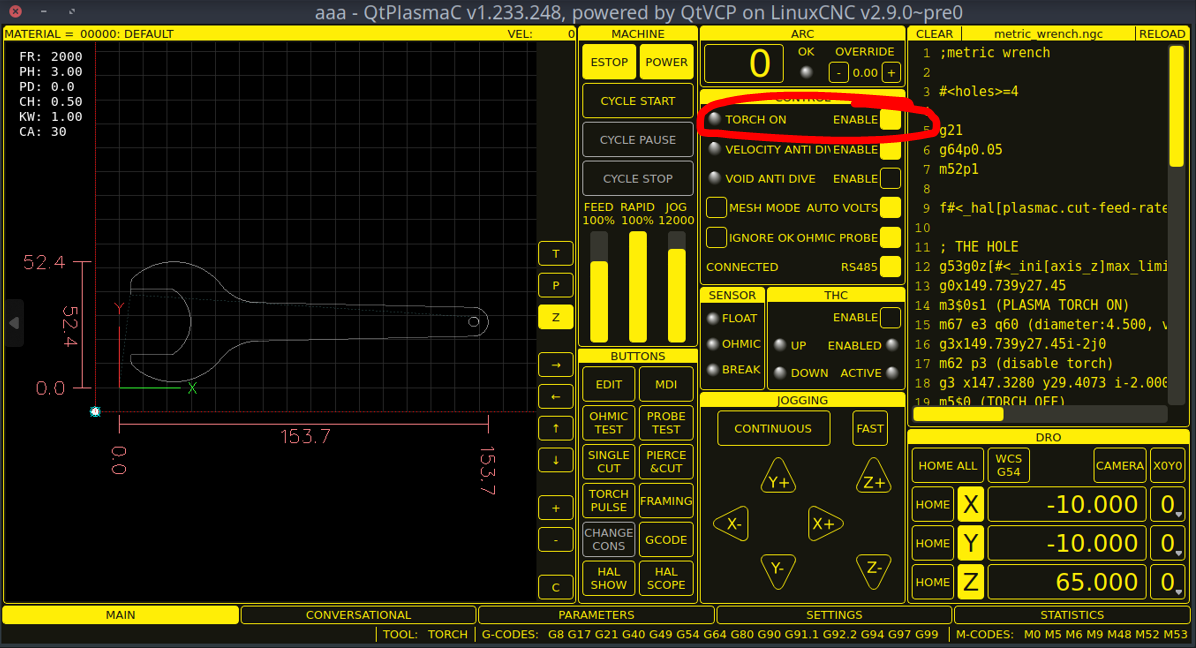

| − | * Dry run with Torch Off by making sure the torch button is not checked. | + | *Dry run with Torch Off by making sure the torch button is not checked. |

| − | * [[File:Torch Button.png]] | + | *[[File:Torch Button.png]] |

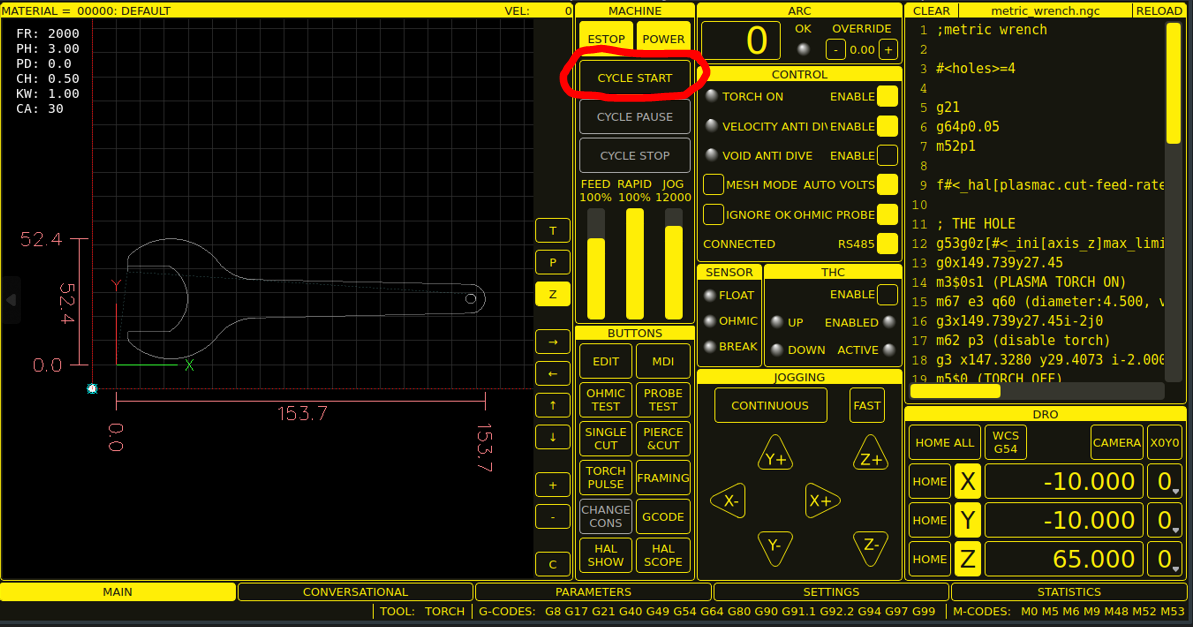

| − | * If everything looks correct you are ready to test run the program via the Cycle Start Button | + | *If everything looks correct you are ready to test run the program via the Cycle Start Button |

| − | * [[File:Cycle Start.png]] | + | *[[File:Cycle Start.png]] |

| − | * Press Play button & have your hand over the escape key on keyboard or on the E-Stop. | + | *Press Play button & have your hand over the escape key on keyboard or on the E-Stop. |

| − | * If Dry run goes well you can now turn on the Plasma Cutter via clicking the torch button) | + | *If Dry run goes well you can now turn on the Plasma Cutter via clicking the torch button) |

| − | * Set Amperage accordingly on the front of the machine to the nozzle selected and how it was programmed. | + | *Set Amperage accordingly on the front of the machine to the nozzle selected and how it was programmed. |

| − | * Make sure the compressor is on and the valve is open. | + | *Make sure the compressor is on and the valve is open. |

| − | * Before cutting make sure welding curtains are closed and everyone has proper eye protection. (Shade 5 or above) | + | *Before cutting make sure welding curtains are closed and everyone has proper eye protection. (Shade 5 or above) |

| − | * Treat the torch as if it could turn on at any time. | + | *Treat the torch as if it could turn on at any time. |

| − | * Do Not put your hand under the torch unless the Plasma cutter is Off. | + | *Do Not put your hand under the torch unless the Plasma cutter is Off. |

| − | * You can now press the cycle start button while still hovering over the escape key or E-Stop. | + | *You can now press the cycle start button while still hovering over the escape key or E-Stop. |

| − | * Let the program finish & remove your part or parts. | + | *Let the program finish & remove your part or parts. |

=Clean up= | =Clean up= | ||

Latest revision as of 19:35, 30 March 2023

Contents

Safety

- @TODO (unassigned, no date): Add tips about eye and body protection, dry runs, not turning on the cutter till your ready.

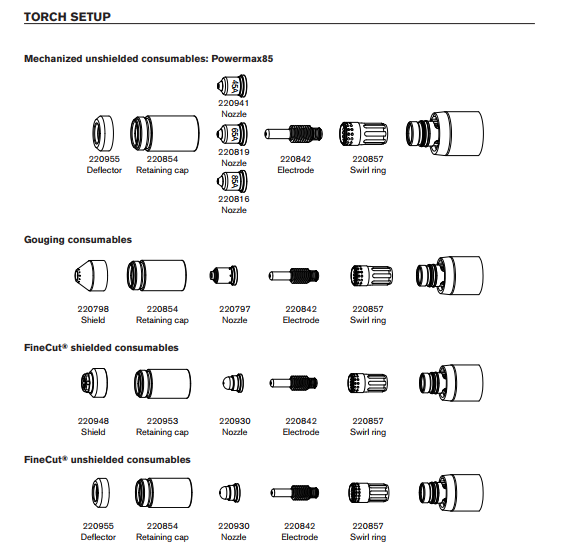

Consumables

The main consumables a member may need to buy are

- Electrode - 220842

- 45A Tip - 220941

- 65A Tip - 220819

- 45A/65A Shield - 220798 (the 220818 drag tip would be used if you were cutting by hand)

- 45A FineCut Tip - 220930

- FineCut Shield - 220948 (the FineCut tip needs a different shield)

You must provide your own electrodes and tips. There is currently a FineCut shield on the plasma cutter, but you may need to provide your own 45A/65A shield.

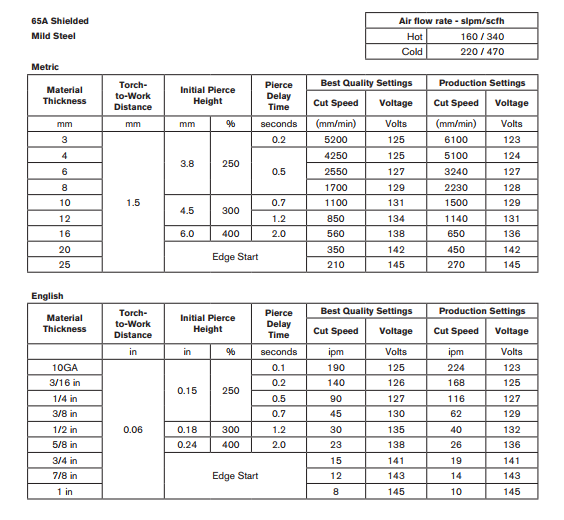

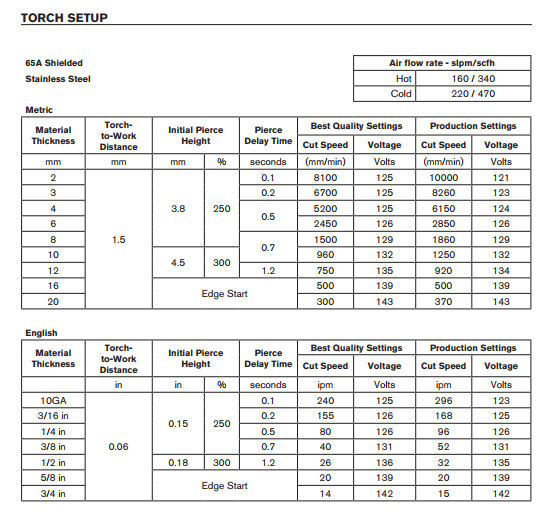

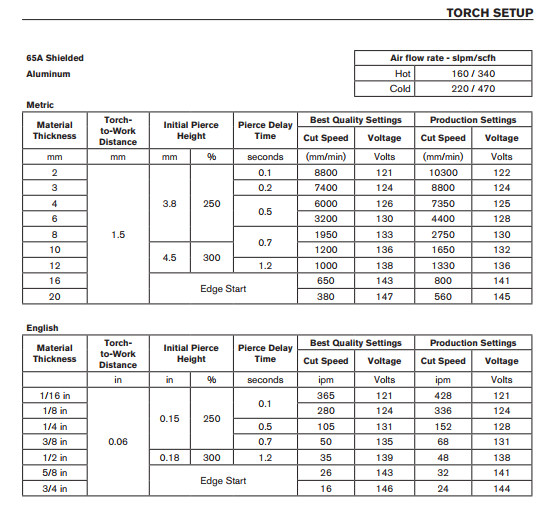

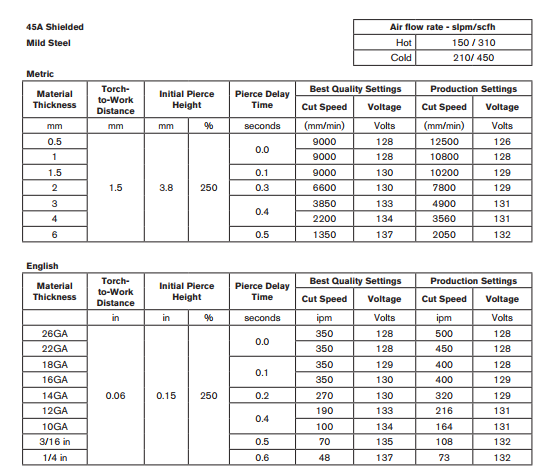

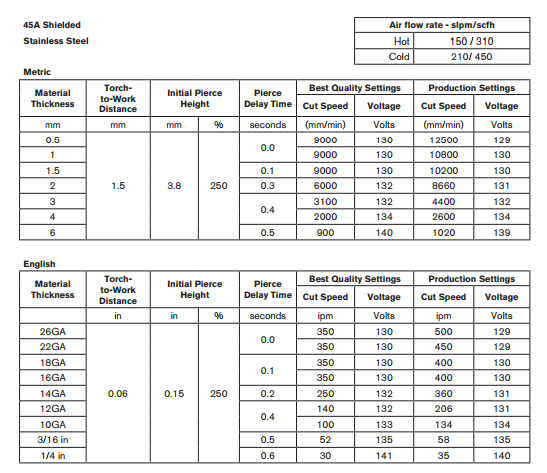

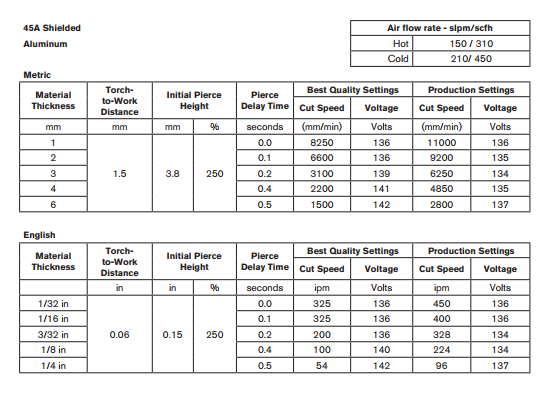

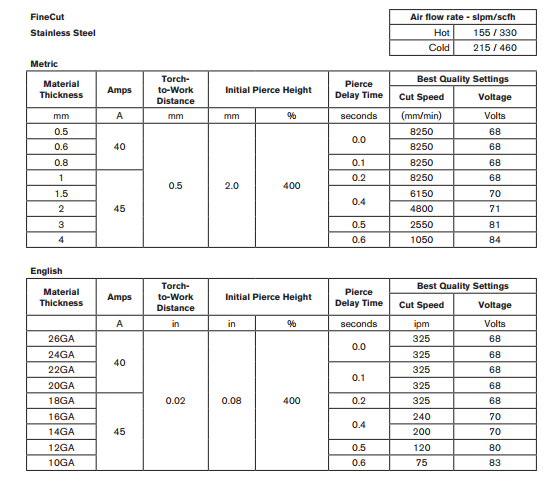

65 Specs

45 Specs

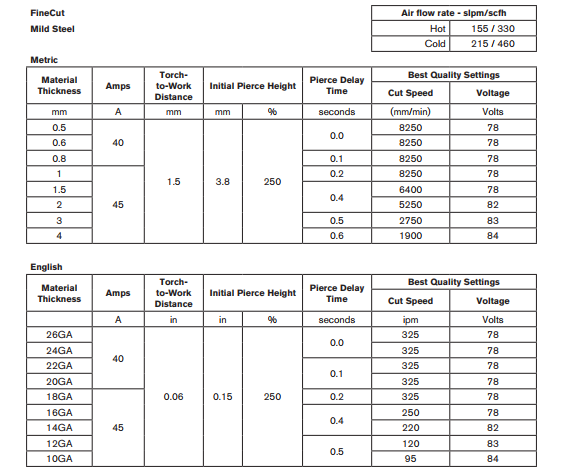

Finecut Specs

Fusion 360

HOW-TO VIDEO: MakeICT Plasma Setup in Fusion 360 (video)

HOW-TO VIDEO: CNC Plasma First Part in Fusion 360 (video)

Fusion 360 can be used to easily generate the G-code for our CNC Plasma Cutter. The following is some useful information that can get you started. To learn more you can check the 2D Profile reference for an explanation of each of the 2D profile settings.

To get started with default settings that work with MakeICT's plasma table, download the following files.

POST PROCESSOR

The first thing you want to do is to grab the Post-Processor. This will ensure that your G-Code matches what our table needs to operate. This really just replaces the M3 with a pierce probe and adds an M5 to stop the torch.

TEMPLATES

You also want to grab the templates for our table. This is not required, but it will save you from having to track down all of the tool settings yourself.

If you do change the tool settings and the dimensions of your cut parts are important, using ‘Compensation Type: In computer’ under the ‘Passes’ tab is recommended for best accuracy. Using ‘Compensation Type: In control’ will cause errors in LinuxCNC without manual editing of the g-code, and will give inconsistent results.

TOOLS

Finally grab the tool files.

Once you have the files all downloaded you will need to upload them to your Fusion 360 account. You only need to do this once, unless the files change and you need to replace them.

Open Fusion 360

- Go to the upper right corner ... you should see your name

- Click on your name and select "Preferences"

- Under "General" ... select "Manufacture"

- Check the "Enable Cloud Libraries" checkbox and click the OK button.

- On the main window, click on the "Show Data Panel" icon in the upper left hand corner (looks like a 3x3 box grid).

- On the left side of the window, you should see a tab that shows "Projects, Libraries, and Samples". If you do not see this, then at the top you should see a big bold < symbol. Click this, and it should take you to the right place.

- Under Libraries click on Assets

- You should now see 4 folders ... CAMMachines, CAMPosts, CAMTempletes, CAMTools

* CAMPosts - 1 Post Processor File * CAMTempletes - 2 Template Files * CAMTools - 3 Tool Files

- Click on the folder that you want to upload, and then drag the file(s) from your download folder to the dialog, and click the Upload Button.

- Repeat for each folder. To switch to a new folder, you can either click the < at the top and then click on the Assets folder again. Or, on the far left, you should see a the folder you are working on (A triangle symbol followed by > followed by the Folder Name). Click on the triangle, and it will show you all of the folders. If you click on the > symbol, it will give you a drop down with all of the folders.

Now you are ready to begin using Fusion 360 to design your job.

Some basic steps:

Create Sketch

- Start a new Model

- Select the X/Y plane (red/green)

- Create a new sketch

- Insert an image or SVG ... or you can draw you sketch by hand.

- Make sure you have extruded your drawing (especially if you are using an image or svg). The depth does not matter, it just has to be extruded.

Switch to MANUFACTURE mode

- Add a new setup

- Select "Cutting" operation.

- Click on the bottom left corner of your drawing to select the anchor point.

- Right click on the setup you just created, and select "Create From Template".

- You should have two templates that you added earlier. Use the "MakeICT no leadin or Kerf" for the cases where a quick generation time and getting every pierce is required. The "MakeICT .125 lead in with Kerf" is recommended for dimensional parts but suffer from slower generation time and instability if multiple holes are smaller than .125in.

- You should now have a new tool showing ... it will have a red circle with an exclamation mark. If you don't see this, click the little triangle to the left of the setup.

- Right click on the new tool, and select edit.

- Click on Tool and select the tip size that you will be using for cutting. This should be on the left side under the Cloud section.

- Select the correct material size.

- Switch to Geometry, select the area to cut.

- If you have small parts that may fall into the water, you can add tabs at desired points. Typically you just want one tab per item, to make it easier to remove in the end.

- Click OK to close the edit dialog.

- You should now see the tool path on the drawing. You can right click on the setup to simulate the operation if you want to see how it will cut.

- Final step is to apply the Post-Processor. This will generate the G-Code that you will load on the plasma cutter. Right click on the setup and select Post Process.

- Make sure that the "Configuration Folder" says <My Cloud Posts>. If it doesn't, click the Setup Button, an switch it to Cloud

- You should only have one option, but make sure that the Post Configuration section has the MakeICT plasma processor selected.

- At the bottom Left, change the Units to Inches.

- Change the Output Folder to the location you want to save your G-Code. You will need this on a USB flash drive, to put it on the plasma computer.

Ready to move to the Plasma

Sheetcam

- Open Sheetcam in windows or Linux.

- Click File - New part - Click yes if prompted.

- Choose file you wish to add .svg or .dxf.

- Part should be loaded into Sheetcam.

- Change X & Y coordinates to .15 at the bottom of the screen.

- Click operation - Plasma cut..

- Choose correct tool & layer.

- Check for lead ins and lead in length - Click ok.

- Look at true width by clicking

- Check starting points.

- Click Edit start points if they need to be modified.

- If everything looks good click run post processor

- Title accordingly and save as .ngc

Linuxcnc

- notes - at this time the THC and the Ohmic touchoff are not wired up. make sure they are not selected. Will post here when that changes along with a tutorial on using them.

- Turn on Computer & Table power.

- DO NOT TURN ON PLASMA CUTTER!

- Login

- PC Login: plasma

- PC Password: linuxcnc

- Open Linuxcnc from the desktop.

- Click power button (Top Middle of the Screen), if the power button is disabled/greyed out make sure the estop isnt pressed

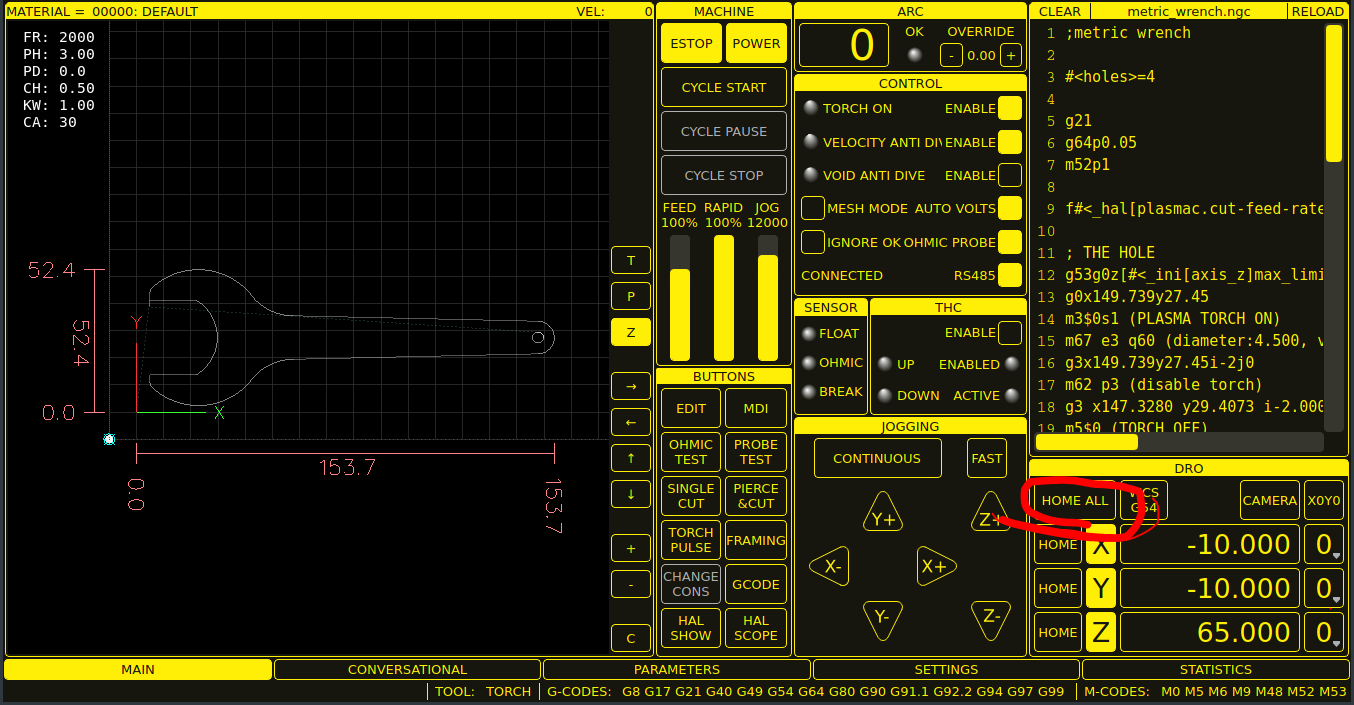

- Click the "Home All" button in the Lower Right.

- Move the machine with the arrow keys on the keyboard or with the GUI to the material and position it according to your fusion 360 setup file (e.g. for most files this is the lower left portion of the material)

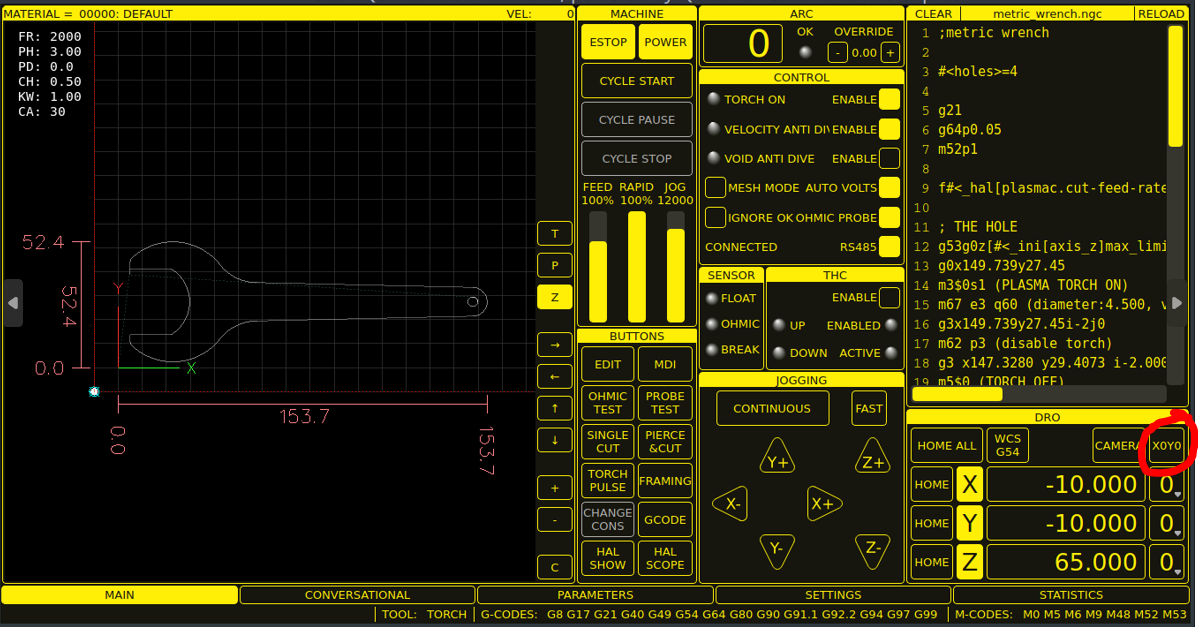

- Click open touch off button note only the x and y need to be touched off

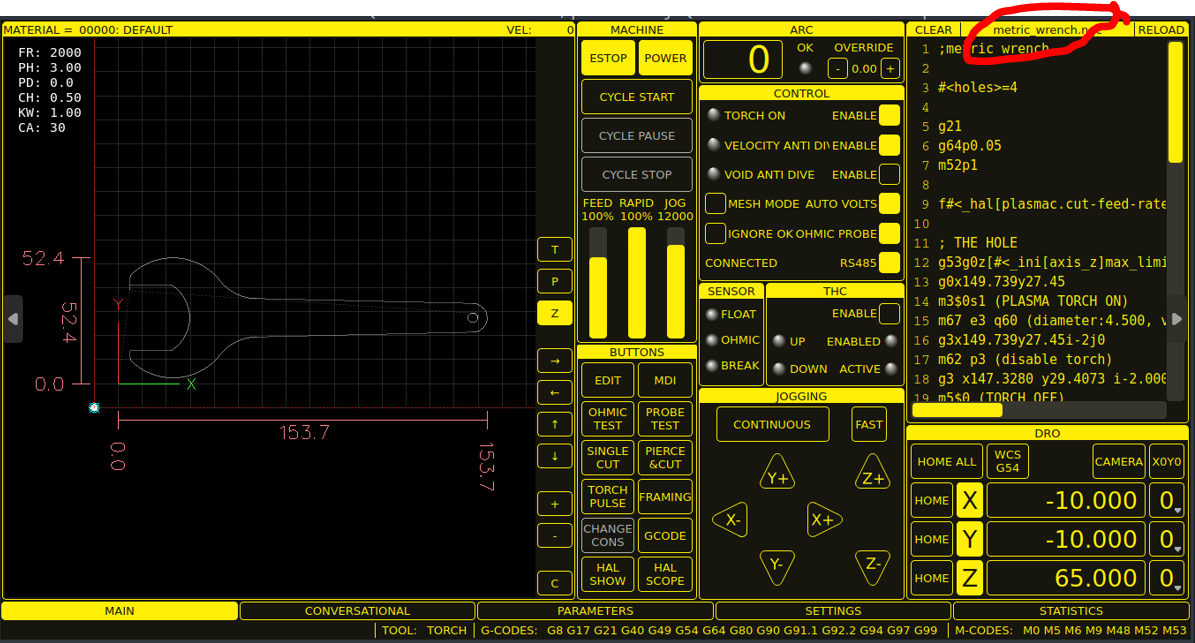

- Click the file button to select your file

- Choose the correct .ngc file.

- Double check size measurements on screen to material size..

- Dry run with Torch Off by making sure the torch button is not checked.

- If everything looks correct you are ready to test run the program via the Cycle Start Button

- Press Play button & have your hand over the escape key on keyboard or on the E-Stop.

- If Dry run goes well you can now turn on the Plasma Cutter via clicking the torch button)

- Set Amperage accordingly on the front of the machine to the nozzle selected and how it was programmed.

- Make sure the compressor is on and the valve is open.

- Before cutting make sure welding curtains are closed and everyone has proper eye protection. (Shade 5 or above)

- Treat the torch as if it could turn on at any time.

- Do Not put your hand under the torch unless the Plasma cutter is Off.

- You can now press the cycle start button while still hovering over the escape key or E-Stop.

- Let the program finish & remove your part or parts.

Clean up

- Use rags to clean off any water that may be on the machine

- Wipe rails and torch shield off with rags.

- Sweep the floor and pick up any trash.

Shutdown

- When finished Shut off the Plasma cutter first!

- Then shut off the table power and shut down the PC.

- Shut off Compressor and clean up any messes you have made.

@TODO (unassigned, no date): Add instructions for setting up sheetcam post processor on personal equipment.