Electronics and Rapid Prototyping

Details: missing details and access policies

Contents

General Information

MakeICT's Electronics and Rapid Prototyping lab is an enclosed 200 sq ft area dedicated to creating and debugging electronics, as well as some rapid prototyping capabilities.

James Seymour is the Benevolent Dictator over the electronics and rapid prototyping lab.

Classes

Machine Access Policy

Clean up! Users are responsible for clean up after themselves; failure to which may result in loss of E&RP Privileges.

Scopes and Analyzers

Use of the Scopes and Analyzers requires certification from a reasonably knowledgeable member (when in doubt ask).

- List of known Scope and analyzer users is listed below

Circuit Design and Fabrication

Use of the Curcuit Board Mill and or SMD Circuit Work Station requires attendance in the Circuit Design and fabrication workshop or certification from an approved peer-certifier.

- Any member who has been certified to use the circuit fabrication equipment may peer-certify other members

- Certification instruction must at least include

- Fundamental knowledge of circuit board milling principles

- Fundamental knowledge of soldering and solder reflow

- Proper use and control of the LinuxCNC software

- Basic circuit design

- Certification must be documented (link to instructions or form) prior to use

- List of circuit fabrication users below

LASER Cutter

Use of the LASER cutter requires attendance in LASER Cutter Basics Class

- Certification must be documented (link to instructions or form) prior to use

- List of LASER Cutter Certified users is listed below

FabLab Area Safety

- Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help.

- Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify the FabLab BD OR Mike Doolittle.

- NEVER ASSUME A TOOL IS PROPERLY ADJUSTED. Always check the tool prior to use.

- NEVER MODIFY OR HACK THE 3D PRINTER, FOAM CUTTER OR LASER CUTTER.

Equipment List

| Picture | What | Manufacturer | Model | Power | Status | Expert |

|---|---|---|---|---|---|---|

|

RD-500S II Area Array Rework System | Den-on Instruments | RD-500S II | 110 | Not yet | James Seymour |

|

Logic Analyzer | Tektronix | 1240 | 110 | Working | James Seymour |

|

Programable Spectrum Analyzer | Tektronix | 492P | 110 | Working | James Seymour |

|

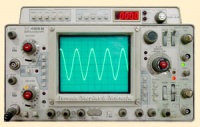

Oscilloscope | Tektronix | 465B | 110 | Working | James Seymour |

|

Lead Free Reflow Oven | Qinsi Technology | QS-5100 | 110 | Working | James Seymour |

|

Soldering Station with Heat Gun | Arksen | 992D | 110 | Working | James Seymour |

Rapid Prototyping

| Picture | What | Manufacturer | Model | Power | Status | Expert |

|---|---|---|---|---|---|---|

|

3-axis CNC Machine | Probotix | Fireball V90 | 110 | Working | ?? |