Difference between revisions of "FabLab Area"

| Line 147: | Line 147: | ||

|} | |} | ||

| − | '''Maintenance Technicians''' | + | '''3D Printer Maintenance Technicians''' |

{| class="wikitable sortable" | {| class="wikitable sortable" | ||

|- | |- | ||

Revision as of 01:09, 15 October 2015

Details: missing details and access policies

Contents

- 1 General Information

- 2 Classes

- 3 Machine Access Policy

- 4 FabLab Area Safety

- 5 LASER Cutter Specific Safety

- 6 Equipment List

- 7 3D Printer Users (to be changed to Certified Users once approved)

- 8 Foam Cutter Users (to be changed to Certified Users once approved)

- 9 LASER Cutter Approved Users (to be changed to Certified Users once approved)

General Information

MakeICT's FabLab is an open 300 sq ft area dedicated to fabrication and rapid prototyping. Here is where you can test ideas, and concepts before moving on to more expensive materials or processes. Or, simply enjoy the creative process and see what you can make. The FabLab currently houses 3D printers, foam cutter, and LASER engraver/cutter.

Per MakeICT policy, all machinery and tools require prior instruction and certification before use. We want all our members and guests to be safe, and the equipment kept in top condition so all can enjoy.

Bryan Barr is the Benevolent Dictator over the FabLab.

Classes

- Intro to CNC: a Foam Cutting Workshop

- Intro to 3D Printing

- Advanced 3D Printing and Modeling

- LASER Cutter Basics Class

Machine Access Policy

DRAFT (currently under review)

Clean up! Users are responsible for clean up after themselves; failure to which may result in loss of FABLAB Privileges.

3D Printers

Use of the 3D printers requires attendance in a certification workshop or certification from an approved peer-certifier.

- Any member who has been certified to use the 3D printer may peer-certify other members

- Certification instruction must at least include

- Fundamental knowledge of each printer's working principles

- Proper use and control of each printer

- Software workflow

- How to change filament

- How to pay for material

- Certification must be documented (link to instructions or form) prior to use

- List of 3D Printer approved users is listed below

Foam Cutter

Use of the foam cutter requires attendance in a certification workshop or certification from an approved peer-certifier.

- Any member who has been certified to use the foam cutter may peer-certify other members

- Certification instruction must at least include

- Fundamental knowledge of foam cutter's working principles

- Proper use and control of foam cutter

- Software workflow

- Certification must be documented (link to instructions or form) prior to use

- List of Foam Cutter approved users is listed below

LASER Cutter

- To use the LASER Cutter you, must take the LASER Cutter Basics Class

- Certification must be documented (link to instructions or form) prior to use

- List of LASER Cutter approved users is listed below

FabLab Area Safety

- Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help.

- Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify the FabLab BD OR Mike Doolittle.

- NEVER ASSUME A TOOL IS PROPERLY ADJUSTED. Always check the tool prior to use.

- NEVER MODIFY OR HACK THE 3D PRINTER, FOAM CUTTER OR LASER CUTTER.

LASER Cutter Specific Safety

LASER cutters pose a fire hazard. LASER cutters use a high intensity beam of LASER light that can produce extremely high temperatures as it comes into contact with the materials it is engraving, marking or cutting.

The LASER cutter is a potentially dangerous piece of equipment which must only be operated by members who have received appropriate training and who take due care. The top things to always remember when using the LASER cutter are:

- ONLY USE THE LASER CUTTER IF YOU ARE ON THE LIST OF TRAINED USERS

- NEVER LEAVE THE LASER CUTTER RUNNING UNATTENDED

- NEVER CUT MATERIALS THAT YOU DON'T KNOW ARE SAFE

- NEVER OVERRIDE THE LASER CUTTER SAFETIES

- KNOW WHAT TO DO IF A FIRE BREAKS OUT

- HIT the BIG RED button on the LASER control panel

- A Carbon Dioxide (CO2) fire extinguisher is located next to the LASER cutter

Before starting the LASER cutter:

- Check the cooling solution window in the back of the chiller before starting any project.

After starting the LASER cutter:

- Before cutting make sure the air compressor and the fan motor are on.

- Refer to the cutting manual for appropriate engraving and cutting Power and Speed settings for varied materials.

- Beware of FLAMMABLE materials while using the machines.

- Certain materials are NOT ALLOWED in the LASER cutter including any PVC material, reflective materials

- Watch this video Polymer Identification by Burnination

- You should read this (pdf) chemistry lab written by [David A. Katz] to learn how to identify what type of plastic it is

Tips:

- The LASER cutter will generally not cut anything greater than 0.25” (6mm), anything thicker will require several passes.

Equipment List

| Picture | What | Manufacturer | Model | Power | Status | Expert | How To |

|---|---|---|---|---|---|---|---|

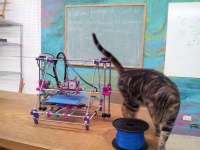

|

3D Printer | SeeMeCNC | Rostock Max v2 | 110 | Working | Bryan Barr | |

|

3D Printer | RepRap | 110 | Working | James Lancaster | ||

|

3D Printer | Ultimaker | Ultimaker II | 110 | Working | Tom McGuire | |

|

Foam Cutter | Tom McGuire | 110 | Working | Tom McGuire | ||

|

LASER Cutter | Rabbit Laser | QX1290 | 230 | Working | Mike Doolittle |

|

3D Printer Users (to be changed to Certified Users once approved)

| Name | Notes | Certification Date | Peer Certified Name |

|---|---|---|---|

| Bryan Barr | FabLab BD | ||

| James Lancaster | 3D Printer instructor | ||

| Mike Doolittle | |||

| Dustin Richey | |||

| Dom Canare | Mentor | ||

| Tom McGuire | Mentor | ||

| Kip | Mentor | ||

| Jeff Eck | |||

3D Printer Maintenance Technicians

| Name | Notes |

|---|---|

| Bryan Barr | FabLab BD |

| James Lancaster | 3D Printer instructor |

| Tom McGuire | Mentor |

Foam Cutter Users (to be changed to Certified Users once approved)

| Name | Notes | Certification Date |

|---|---|---|

| Bryan Barr | FabLab BD | |

| Tom McGuire | Foam Cutter instructor | |

| Dom Canare |

Maintenance Technicians

| Name | Notes |

|---|---|

| Tom McGuire | Foam Cutter instructor |

LASER Cutter Approved Users (to be changed to Certified Users once approved)

| Name | Notes | Certification Date |

|---|---|---|

| Bryan Barr | FabLab BD | |

| Mike Doolittle | LASER Cutter instructor | |

| John Alexander | ||

| Jerry Carpenter | Mentor | |

| David Springs | ||

| William Davisson | ||

| Brad Cooley | ||

| Ivan Quiroz | ||

| Jonny Fosnight | ||

| Stephen Reckers | ||

| Mike Hutton |

Maintenance Technicians

| Name | Notes |

|---|---|

| Bryan Barr | FabLab BD |

| Mike Doolittle | LASER Cutter instructor |

| Jerry Carpenter | Mentor |