Difference between revisions of "FabLab Area"

From MakeICT Wiki

Jump to navigationJump to search| Line 19: | Line 19: | ||

=== Laser Engraver/Cutter === | === Laser Engraver/Cutter === | ||

| − | * To use the Laser Engraver/Cutter you, must take the [[Laser | + | * To use the Laser Engraver/Cutter you, must take the [[Laser Cutter Basics Class]] (this takes affect 10/3/15) |

* Certification is under construction | * Certification is under construction | ||

* List of Laser Engraver/Cutter approved users is listed below | * List of Laser Engraver/Cutter approved users is listed below | ||

Revision as of 23:29, 27 September 2015

Attention! This page or section is out of date. Help us out by modifying this page.

Details: missing details and access policies

Details: missing details and access policies

Contents

General Information

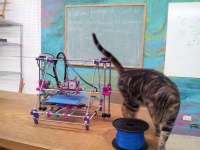

MakeICT's FabLab is an open 300 sq ft area dedicated to fabrication and rapid prototyping. Here is where you can test ideas, and concepts before moving on to more expensive materials or processes. Or, simply enjoy the creative process and see what you can make. The FabLab currently houses 3D printers, foam cutter, and laser engraver/cutter.

Per MakeICT policy, all machinery and tools require prior instruction and certification before use. We want all our members and guests to be safe, and the equipment kept in top condition so all can enjoy.

Bryan Barr is the Benevolent Dictator over the FabLab.

Machine Access Policy

3D Printers

- To use the 3D Printers, you must take the Intro to 3D Printing Class (TBD)

- Certification is under construction

- List of Laser 3D Printer approved users is listed below

Foam Cutter

- To use the Foam Cutter, you must take the Intro to CNC: A Foam Cutting Workshop (TBD)

- Certification is under construction

- List of Foam Cutter approved users is listed below

Laser Engraver/Cutter

- To use the Laser Engraver/Cutter you, must take the Laser Cutter Basics Class (this takes affect 10/3/15)

- Certification is under construction

- List of Laser Engraver/Cutter approved users is listed below

Classses

- Intro to CNC: a Foam Cutting Workshop

- Intro to 3D Printing

- Advanced 3D Printing and Modeling

- Laser Cutter Basics Class

3D Printer Safety

- Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help.

- Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify the woodshop BD.

- NEVER ASSUME A TOOL IS PROPERLY ADJUSTED. Always check the tool prior to use.

Foam Cutter Safety

- Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help.

- Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify the woodshop BD.

- NEVER ASSUME A TOOL IS PROPERLY ADJUSTED. Always check the tool prior to use.

Laser Cutter Safety

- Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help.

- Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify the woodshop BD.

- NEVER ASSUME A TOOL IS PROPERLY ADJUSTED. Always check the tool prior to use.

Equipment List

| Picture | What | Manufacturer | Model | Power | Status | Expert | How To |

|---|---|---|---|---|---|---|---|

|

3D Printer | SeeMeCNC | Rostock Max v2 | 110 | Working | Bryan Barr | [MatterControl Wiki] |

|

3D Printer | RepRap | 110 | Working | James Lancaster | Information | |

|

3D Printer | Ultimaker | Ultimaker II | 110 | Working | Tom McGuire | instructions |

|

Foam Cutter | Tom McGuire | 110 | Working | Tom McGuire | Basic Use Guidelines | |

|

Laser Cutter | Rabbit Laser | QX1290 | 230 | Working | Mike Doolittle | Laser Cutter Guidelines |

3D Printer Approved Users

| Name | Notes | Certification Date | Peer Certified Name |

|---|---|---|---|

| Bryan Barr | FabLab BD | ||

| Mike Doolittle | |||

| Dustin | |||

| Dom | |||

| Tom | |||

| Kip | |||

| Jeff Eck | |||

Foam Cutter Approved Users

| Name | Notes | Certification Date |

|---|---|---|

| Bryan Barr | FabLab BD | |

| Tom | Foam Cutter instructor | |

| Dom |

Laser Cutter Approved Users

| Name | Notes | Certification Date |

|---|---|---|

| Bryan Barr | FabLab BD | |

| Mike Doolittle | Laser Cutter instructor | |

| Jerry Carpenter | ||

| David Springs | ||

| William Davisson | ||

| Brad Cooley | ||

| Ivan Quiroz | ||

| Jonny Fosnight | ||

| John Alexanders | ||

| Stephen Reckers | ||

| Mike Hutton |