Difference between revisions of "RepRap Prusa Mendel"

| Line 1: | Line 1: | ||

[[Category:FabLab Equipment]] | [[Category:FabLab Equipment]] | ||

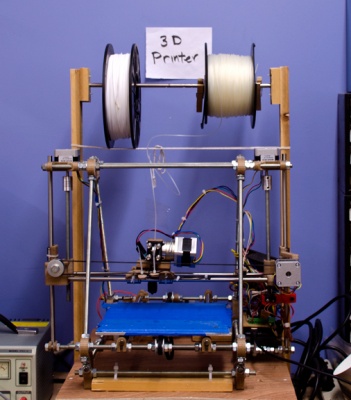

| + | [[File:Reprap Mendel Prusa.jpg|x400px|left]] | ||

| + | |||

== Assembly == | == Assembly == | ||

The 3D printing Special Interest Group made the modified Mendel Prusa printer for MakeICT. The printer's plastic parts were created on a member's Mendel Prusa which was built from a Makergear kit. The printer's electronics are a Arduino Mega and a Ramps shield. The Ramps shield was made at MakeICT using the toner transfer method, and the soldering was done by another member. The bed, unlike most 3D printers, is actually an aluminum bed with clamps. The holes were cut twice. Once by hand, and once on the V90 router, for precise drilling. You can see this difference if you look at the bottom of the printer. The belt clamps are also aluminum, which fit into holes on the bed, and were cut on the small CNC mill that resides at MakeICT. Assembly was completed over several Open Hack nights by the 3D printing special interest group. | The 3D printing Special Interest Group made the modified Mendel Prusa printer for MakeICT. The printer's plastic parts were created on a member's Mendel Prusa which was built from a Makergear kit. The printer's electronics are a Arduino Mega and a Ramps shield. The Ramps shield was made at MakeICT using the toner transfer method, and the soldering was done by another member. The bed, unlike most 3D printers, is actually an aluminum bed with clamps. The holes were cut twice. Once by hand, and once on the V90 router, for precise drilling. You can see this difference if you look at the bottom of the printer. The belt clamps are also aluminum, which fit into holes on the bed, and were cut on the small CNC mill that resides at MakeICT. Assembly was completed over several Open Hack nights by the 3D printing special interest group. | ||

Revision as of 23:53, 28 January 2016

Assembly

The 3D printing Special Interest Group made the modified Mendel Prusa printer for MakeICT. The printer's plastic parts were created on a member's Mendel Prusa which was built from a Makergear kit. The printer's electronics are a Arduino Mega and a Ramps shield. The Ramps shield was made at MakeICT using the toner transfer method, and the soldering was done by another member. The bed, unlike most 3D printers, is actually an aluminum bed with clamps. The holes were cut twice. Once by hand, and once on the V90 router, for precise drilling. You can see this difference if you look at the bottom of the printer. The belt clamps are also aluminum, which fit into holes on the bed, and were cut on the small CNC mill that resides at MakeICT. Assembly was completed over several Open Hack nights by the 3D printing special interest group.

Features

This printer is the best to use for flexible filaments (such as ninjaflex) due to having the extruder mounted directly to the nozzle.

Use

This printer is controlled through the software Pronterface running on the attached computer.

If you have not been instructed on use, please see one of the people who have (Please see Dominic, Tom, Christian, or James L, or ask questions on the mailing list.)