Difference between revisions of "FabLab Area"

From MakeICT Wiki

Jump to navigationJump to searchDavid Miller (talk | contribs) m (Removed the plotter) |

|||

| (127 intermediate revisions by 16 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | ==General Information== | |

| + | MakeICT's FabLab is an open area dedicated to fabrication and rapid prototyping. Members can test ideas and concepts before moving on to more expensive materials or processes, or simply enjoy the creative process of making. | ||

| − | + | If you have any issues with FabLab equipment, please e-mail [mailto:fablab@makeict.org fablab@makeict.org]. | |

| − | |||

| − | |||

| − | [[ | + | [[FabLab Area Meetings]] |

| − | + | <br /> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | ==Access Policy== |

| − | + | {{:FabLab_Access_Policy}} | |

| − | + | ==FabLab Area Safety== | |

| + | |||

| + | #Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help on the [https://talk.makeict.org MakeICT forum] or email [mailto:fablab@makeict.org fablab@makeict.org]. | ||

| + | #Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify [mailto:fablab@makeict.org FabLab leadership]. | ||

| + | #Never assume a tool is properly adjusted; always check the tool prior to use. | ||

| + | #Never modify or hack any equipment. | ||

| + | #If something is wrong, leave a note in an obvious place on the troubled equipment and e-mail [mailto:fablab@makeict.org fablab@makeict.org]. | ||

| + | |||

| + | ==Equipment List== | ||

| + | <onlyinclude> | ||

| + | {| class="wikitable sortable" | ||

| + | |- | ||

| + | !Picture | ||

| + | !What | ||

| + | !Manufacturer | ||

| + | !Model | ||

| + | !Status | ||

| + | !Resources | ||

| + | |- | ||

| + | |[[File:Laser_cutter.jpg|200px]] | ||

| + | |[[Laser Cutter]] | ||

| + | |Rabbit Laser | ||

| + | |[[Laser Cutter|QX1290]] | ||

| + | |Operational | ||

| + | | | ||

| + | MakeICT resources | ||

| − | + | *[[Laser Cutter]] | |

| − | |||

| − | * | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | External resources | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *[http://www.rabbitlaserusa.com/ManualsTutorials.html Manuals] | |

| − | * | + | *[http://www.rabbitlaserusa.com/laser_RL1290.html QX1290 Specs] |

| − | * | ||

| − | |||

| − | + | |- | |

| − | + | |[[File:Laser_cutter.jpg|200px]] | |

| − | + | |[[Laser Cutter]] | |

| − | + | |Rabbit Laser | |

| − | + | |[[Laser Cutter|QX1290]] | |

| + | |Operational | ||

| + | | | ||

| + | MakeICT resources | ||

| − | + | *[[Laser Cutter]] | |

| − | |||

| − | + | External resources | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *[http://www.rabbitlaserusa.com/ManualsTutorials.html Manuals] | |

| − | + | *[http://www.rabbitlaserusa.com/laser_RL1290.html QX1290 Specs] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | External resources | |

| − | |||

|- | |- | ||

| − | + | |[[File:MK4 print.jpg|left|200x200px|alt=]] | |

| + | |[[3D Printer]] | ||

| + | |Prusa3D | ||

| + | |i3 MK4 | ||

| + | |Operational | ||

| + | |MakeICT resources | ||

| + | |||

| + | *[[Prusa i3 MK4]] | ||

|- | |- | ||

| − | | [[File: | + | |[[File:Original-prusa-i3-mk3s-3d-printer.jpg|200x200px]] |

| + | |[[3D Printer]] | ||

| + | |Prusa3D | ||

| + | |i3 Mk3S+ | ||

| + | |Operational | ||

| + | |MakeICT resources | ||

| + | |||

| + | *[[Prusa i3 MK3]] | ||

|- | |- | ||

| − | | [[File: | + | |[[File:Original-prusa-i3-mk3s-3d-printer.jpg|200x200px]] |

| + | |[[3D Printer]] | ||

| + | |Prusa3D | ||

| + | |i3 Mk3S+ | ||

| + | |Operational | ||

| + | |MakeICT resources | ||

| + | |||

| + | *[[Prusa i3 MK3]] | ||

|- | |- | ||

| − | | [[File: | + | |[[File:Original-prusa-i3-mk3s-3d-printer.jpg|200x200px]] |

| + | |[[3D Printer]] | ||

| + | |Prusa3D | ||

| + | |i3 Mk3S+ | ||

| + | |Operational | ||

| + | |MakeICT resources | ||

| + | |||

| + | *[[Prusa i3 MK3]] | ||

| + | |||

|- | |- | ||

| − | | [[File: | + | |[[File:Original-prusa-i3-mk3s-3d-printer.jpg|200x200px]] |

| + | |[[3D Printer]] | ||

| + | |Prusa3D | ||

| + | |i3 Mk3S+ | ||

| + | |Operational | ||

| + | |MakeICT resources | ||

| + | |||

| + | *[[Prusa i3 MK3]] | ||

|- | |- | ||

| − | | [[File: | + | |[[File:Ultimaker II.jpeg|200px]] |

| − | | | + | |[[3D Printer]] |

| + | |Ultimaker | ||

| + | |[[Ultimaker 2]] | ||

| + | |Operational | ||

| + | | | ||

| + | MakeICT resources | ||

| − | + | *[[Ultimaker 2]] | |

| − | + | ||

| + | External resources | ||

| + | |||

| + | *[https://ultimaker.com/en/support/ultimaker-3d-printers/ultimaker-2 Overview] | ||

| + | *[https://ultimaker.com/en/products/ultimaker-2#specifications Specs] | ||

| + | *[http://support.3dverkstan.se/article/23-a-visual-ultimaker-troubleshooting-guide Troubleshooting] | ||

|- | |- | ||

| − | + | |[[File:Graphtec_fc2200.gif|200px]] | |

| + | |[[Vinyl Cutting And Plotting|Graphtec Plotter/Vinyl Cutter]] | ||

| + | |Graphtec | ||

| + | |[[Graphtec_FC2200-90/EX|Graphtec_FC2200-90/EX]] | ||

| + | |Operational | ||

| + | | | ||

| + | *[[Graphtec FC2200-90/EX|Graphtec Plotter]] | ||

|- | |- | ||

| − | | | + | |[[File:Lbm.jpg|alt=Little Blue Mill|left|180x180px]] |

| + | |CNC Mini Milling Machine | ||

| + | |Originally Sherline | ||

| + | |Little Blue Mill | ||

| + | |Operational | ||

| + | |[[Little Blue Mill]] | ||

|- | |- | ||

| − | | | + | |[[File:Foam-Cutter.jpg|200px]] |

| + | |[[Foam Cutter]] | ||

| + | |[[User:Tom McGuire|Tom McGuire]] | ||

| + | |[[Foam Cutting Machine]] | ||

| + | |Needs Maintenance | ||

| + | | | ||

| + | *[[Foam Cutting Machine]] | ||

|- | |- | ||

| − | | | + | |[[File:VacuumFormer.jpg|alt=Vacuum former|left|200x200px]] |

| + | |[[Vacuum Former]] | ||

| + | |Industrial Arts Supply Co. | ||

| + | |Nichols model 10-B Therm-O-Vac | ||

| + | |Operational | ||

| + | | | ||

| + | MakeICT resources | ||

| + | |||

| + | *[[Vacuum Former]] | ||

|- | |- | ||

| − | | | + | |[[File:Xbox-kinect.jpg|200px]] |

| + | |[[Kinect Scanner]] | ||

| + | |Microsoft | ||

| + | |[[Kinect]] | ||

| + | |Operational | ||

| + | | | ||

| + | *[[Kinect Scanner]] | ||

|- | |- | ||

| − | | | + | | |

| + | |[[Turntable for Kinect]] | ||

| + | |[[User:James Lancaster|James Lancaster]] | ||

| + | |[[Turntable]] | ||

| + | |Operational | ||

| + | | | ||

| + | *[[Kinect Scanner]] | ||

|- | |- | ||

| − | | | + | |[[File:PlasticInjection.jpg|alt=Plastic injection molding machine|left|200x200px]] |

| + | |Plastic Injection Molding Machine | ||

| + | | | ||

| + | | | ||

| + | |Needs tested | ||

| + | |MakeICT resources | ||

|- | |- | ||

| − | | | + | | |

| + | |CNC Mini Mill | ||

| + | |Sherline | ||

| + | |Black Sherline Mill | ||

| + | |Needs repaired | ||

| + | |[[Sherline_CNC_Mill]] | ||

|- | |- | ||

| − | + | | | |

| − | | | + | |CNC Mini Lathe |

| − | + | |Emco | |

| − | | | + | |Emco Lathe |

| − | | | + | |Needs repaired and setup |

| − | | | + | | |

| − | | | ||

|} | |} | ||

| + | </onlyinclude> | ||

| − | == | + | ==Retired Equipment== |

| + | <onlyinclude> | ||

{| class="wikitable sortable" | {| class="wikitable sortable" | ||

|- | |- | ||

| − | ! | + | !Picture |

| + | !What | ||

| + | !Manufacturer | ||

| + | !Model | ||

| + | !Status | ||

| + | !Resources | ||

|- | |- | ||

| − | | | + | |[[File:Reprap Mendel Prusa.jpg|200px]] |

| + | |[[3D Printer]] | ||

| + | |[[User:James Lancaster|James Lancaster]] | ||

| + | |[[RepRap Prusa Mendel]] | ||

| + | |Retired | ||

| + | | | ||

| + | MakeICT resources | ||

| + | External resources | ||

| + | |||

| + | *[http://reprap.org/wiki/Prusa_Mendel_(iteration_2) RepRap.org source] | ||

| + | * | ||

|- | |- | ||

| − | | | + | | |

| + | |CNC Router | ||

| + | |Probotix | ||

| + | |Fireball V90 | ||

| + | |Retired | ||

| + | |[[V90]] | ||

|- | |- | ||

| − | | | + | |[[File:Rostock_Max_V2.jpeg|200px]] |

| − | | | + | |[[3D Printer]] |

| + | |SeeMeCNC | ||

| + | |[[Rostock Max V2]] | ||

| + | |Retired! | ||

| + | | | ||

| + | MakeICT resources | ||

| − | + | *[[Rostock Max V2]] | |

| − | |||

|- | |- | ||

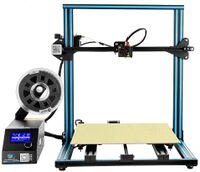

| − | + | |[[File:Creality-cr10s.jpg|200x200px]] | |

| − | |- | + | |[[3D Printer]] |

| − | + | |Creality3D | |

| − | | | + | |CR-10s |

| − | | | + | |Retired |

| − | |- | + | |MakeICT resources |

| − | | | + | |

| − | | | + | *[[Creality CR-10S]] |

| − | + | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| + | </onlyinclude> | ||

| + | [[Category:Areas]] | ||

Latest revision as of 17:24, 5 May 2024

Contents

General Information

MakeICT's FabLab is an open area dedicated to fabrication and rapid prototyping. Members can test ideas and concepts before moving on to more expensive materials or processes, or simply enjoy the creative process of making.

If you have any issues with FabLab equipment, please e-mail fablab@makeict.org.

Access Policy

3D Printers and Foam Cutter

- Use of the 3D printers and the Foam Cutter require peer authorization. Visit the 3D Printing and Foam Cutter pages for details.

Laser Cutter

- Use of the Laser Cutter requires authorization by an approved instructor. Classes will be offered on a regular basis for those who need them. Visit the Laser Cutter page for details.

All Equipment

- Equipment requiring authorization may be operated by an unauthorized user only under the direct supervision of an authorized user.

Approved by the board on February 5, 2017

FabLab Area Safety

- Do not use any machine you are not trained on and comfortable using. If at any time you are unsure of what you are doing, stop immediately and ask for help on the MakeICT forum or email fablab@makeict.org.

- Do not use any machine that is not in good working order. Stop, unplug and leave a note on the machine and notify FabLab leadership.

- Never assume a tool is properly adjusted; always check the tool prior to use.

- Never modify or hack any equipment.

- If something is wrong, leave a note in an obvious place on the troubled equipment and e-mail fablab@makeict.org.

Equipment List

| Picture | What | Manufacturer | Model | Status | Resources |

|---|---|---|---|---|---|

|

Laser Cutter | Rabbit Laser | QX1290 | Operational |

MakeICT resources External resources |

|

Laser Cutter | Rabbit Laser | QX1290 | Operational |

MakeICT resources External resources

External resources |

| 3D Printer | Prusa3D | i3 MK4 | Operational | MakeICT resources | |

|

3D Printer | Prusa3D | i3 Mk3S+ | Operational | MakeICT resources |

|

3D Printer | Prusa3D | i3 Mk3S+ | Operational | MakeICT resources |

|

3D Printer | Prusa3D | i3 Mk3S+ | Operational | MakeICT resources |

|

3D Printer | Prusa3D | i3 Mk3S+ | Operational | MakeICT resources |

|

3D Printer | Ultimaker | Ultimaker 2 | Operational |

MakeICT resources External resources |

|

Graphtec Plotter/Vinyl Cutter | Graphtec | Graphtec_FC2200-90/EX | Operational | |

| CNC Mini Milling Machine | Originally Sherline | Little Blue Mill | Operational | Little Blue Mill | |

|

Foam Cutter | Tom McGuire | Foam Cutting Machine | Needs Maintenance | |

| Vacuum Former | Industrial Arts Supply Co. | Nichols model 10-B Therm-O-Vac | Operational |

MakeICT resources | |

|

Kinect Scanner | Microsoft | Kinect | Operational | |

| Turntable for Kinect | James Lancaster | Turntable | Operational | ||

| Plastic Injection Molding Machine | Needs tested | MakeICT resources | |||

| CNC Mini Mill | Sherline | Black Sherline Mill | Needs repaired | Sherline_CNC_Mill | |

| CNC Mini Lathe | Emco | Emco Lathe | Needs repaired and setup |

Retired Equipment

| Picture | What | Manufacturer | Model | Status | Resources |

|---|---|---|---|---|---|

|

3D Printer | James Lancaster | RepRap Prusa Mendel | Retired |

MakeICT resources External resources |

| CNC Router | Probotix | Fireball V90 | Retired | V90 | |

|

3D Printer | SeeMeCNC | Rostock Max V2 | Retired! |

MakeICT resources |

|

3D Printer | Creality3D | CR-10s | Retired | MakeICT resources |