3D Printing

Contents

- 1 About

- 2 Features

- 3 Access Policy

- 4 Use

- 5 Acquisition

- 6 Features

- 7 Access Policy

- 8 Use

- 9 Acquisition

- 10 Features

- 11 Access Policy

- 12 Use

- 13 Acquisition

- 14 Features

- 15 Access Policy

- 16 Use

- 17 Acquisition

- 18 Machine Access Policy

- 19 Filament Fund

- 20 Workflow

- 21 General Use Tips

- 22 References

- 23 3D Printer Authorized Users

About

3D printing is an additive manufacturing process that allows for the creation of real-world, tangible objects from 3D virtual models. MakeICT maintains the following 3D printers:

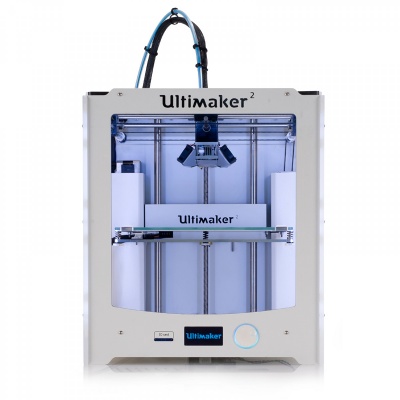

FeaturesDue to its ease of use and ability to produce high quality prints, the Ultimaker 2 is the most popular 3D printer at MakeICT. It has been upgraded with an E3D V6 hotend and geared E3D Titan extruder for increased reliability. Unlike the stock version, it uses 1.75mm filament which is the standard among all of the printers at the makerspace. Access PolicySee 3D Printing for access policy. UseSee 3D Printing#Workflow for workflow information. AcquisitionThis printer was purchased using grant money from the Wichita Community Foundation and the Knight Foundation. !

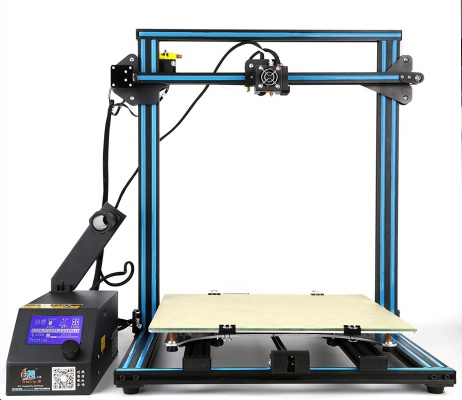

FeaturesThe Rostock has the largest build area of MakeICT's 3D printers. Access PolicySee 3D_Printing#Machine_Access_Policy for access policy. UseSee 3D Printing#Workflow for workflow information. AcquisitionThis printer was purchased with money. The printer has been updated to run on Marlin configuration.h here: Rostock_Configuration ! FeaturesThis printer has the largest build volume of all the printers at MakeICT. Access PolicySee 3D_Printing#Machine_Access_Policy for access policy. UseSee 3D Printing#Workflow for workflow information. AcquisitionThis printer was purchased using funds donated by members during a special fundraising effort. !

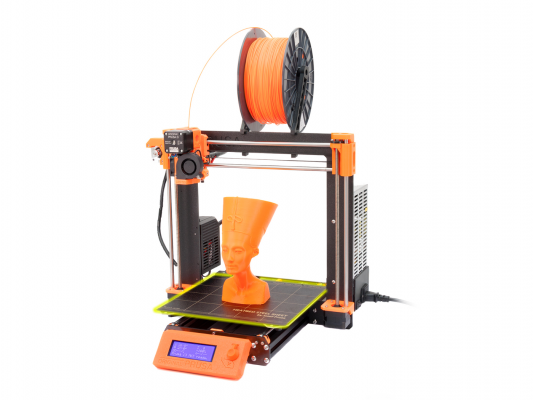

FeaturesThese printers have a number of advanced features that make them easier to use:

Access PolicySee 3D_Printing#Machine_Access_Policy for access policy. UseSee 3D Printing#Workflow for general workflow information. DO NOT SPRAY BED WITH HAIRSPRAY! Before PrintingIn order for prints to adhere properly the bed must be clean. Wipe it down with isopropyl alcohol (NOT acetone!) before a print to ensure that the bed is free of oils and dust. There are some special cases for bed preparation depending on the material used. Certain materials can damage the bed surface if not used properly. Check this chart for more info: https://help.prusa3d.com/en/materials . This will show you which bed is best for the material that you are using. Always check that the correct bed type is selected on the LCD menu before starting your print. Using the wrong setting can damage the bed or prevent proper adhesion. See this link for more information on bed preparation: https://help.prusa3d.com/article/6Gtws6Yqjg-pei-print-surface-preparation Filament Change

Print RemovalDO NOT USE SCRAPERS! Lift the spring steel sheet off of the bed by the front corners. Gently flex the bed in both directions until the print loosens enough to be removed. AcquisitionThis printer was purchased using a combination of membership dues and targeted donations. Thanks to everyone who donated! | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Machine Access Policy

Use of the 3D printers requires authorization from an approved peer-authorizor or attendance in a 3D printer workshop that includes authorization.

- Any member who has been authorized to use the 3D printer may peer-authorize other members

- Authorization instruction must at least include

- Fundamental knowledge of each printer's working principles

- Proper use and control of each printer

- Software workflow

- How to change filament

- How to pay for material

Filament Fund

Printing with filament provided by MakeICT costs $0.04 per gram. After printing, please weigh your print using the provided scale and put the appropriate amount of money in the filament fund jar. If you have any requests for new colors/types of filaments, you can write them on the same jar.

Workflow

Note: This process is under development and may change. Check back here for updates if something changes.

Slicing

Slicing is the process of converting an STL file to the G-Code required to run the printer.

Any slicer with an appropriately configured profile can be used to generate G-Code to run the machines. We have setup Slic3r with profiles for each machine on the design computer in the Fab Lab, and are working to configure the same for Cura. These profiles are available on the Slicer Profiles page on this Wiki.

Slic3r has native support for uploading to Octoprint, just hit the 'Upload to printer' button in the 'Plater' tab. In Cura just export the G-Code file and upload it using the file browser in Octoprint.

When slicing, be sure to use the correct profile for the machine you intend to print on. G-Code generated for one machine WILL NOT work properly on the others.

Printing

Each printer can be run using Octoprint. Thorough instructions on this interface can be found on the Octoprint page. The username and password are 'maker'.

The printers can be reached at the following addresses while connected to the network at MakeICT:

- Rep Rap Mendel: reprap.makeict.org 192.168.9.30

- Ultimaker 2: ultimaker.makeict.org 192.168.9.31

- Rostock Max V2: rostock.makeict.org 192.168.9.32

To run a print: select your file and click the print button.

General Use Tips

When changing from a filament that prints hotter to one that prints cooler (e.g. ABS to PLA) you should do a cold pull to remove the old plastic that is lining the melt chamber. Otherwise there will likely be problems with underextrusion due to the unmelted plastic.(Not necessary or effective with e3d hotends)

- When your print is finished, do not immediately turn off the power; wait until the nozzle has cooled. The Ultimaker and Rostock have actively cooled heatsinks on their hotends, and if power is cut before the nozzle is cool the filament can melt higher up than intended and cause a jam.

- Be careful when removing prints. The glass beds are fairly durable, but can be cracked with excessive force. No hammers, mallets, or other bludgeoning devices are to be used for print removal!

- G-Code files generated for one printer should never be used on another. Re-run the slicer with the appropriate profiles for the machine that is being used

- Check material before starting a print. Make sure it is the correct type, and that there is enough to complete the print.

References

- Slides for 3D Printing Basics Class

- Example files for 3D Printing Basics Class

- Descriptions of the various G-Codes used to run the printers can be found here:

3D Printer Authorized Users

To see authorized users expand this section --->